Have you ever thought about the mechanism behind automated doors in elevators or automobiles or anything that moves automatically? What causes automation to work? The machine behind that automation is the actuator. Let’s learn more about actuators, types of actuators, and how it works in this article.

What Is An Actuator? Define Actuator

An actuator is a machine or device responsible for controlling the motion of other objects, machines, or mechanisms. For example, an actuator creates the motion on doors when you press the door open button in an elevator.

We are living in the age of automation, and automation without actuators is not possible. Actuators are used as tiny devices like a watch to an enormous airplane also.

How does actuator work?

For an actuator to work, it needs a control signal and source of energy. The control signal can be electric current, pneumatic or hydraulic pressure, or even human power. When an actuator receives a control signal, it converts that energy to mechanical motion.

The mechanical motion can be linear or rotational based on the application. Sometimes an actuator can have both types of motion combined, like in the rack and pinion mechanism.

Purpose Of actuators

The job that an actuator can also be done using any manual action or other manually operated devices. For example, you can open an elevator door manually also. Right?

An actuator helps us because it automates the process, so there are fewer chances of errors, let time required to create mechanical motion, and less workforce required to do a job. On top of that, one of the key benefits that an actuator brings is precision in converting energy or motion.

Different Types Of Actuators

There are two types of actuator based on the motion type.

- Linear Actuator

- Rotary Actuator

Linear Actuator

As the name suggests, linear actuators create linear motions. In other words, it creates a push-pull motion in a mechanism or a static body. For example, a rake and pinion mechanism or an elevator door where linear actuators are used.

Rotary Actuator

Rotary actuators create rotary motion in an object or mechanism. For example, automated wheels in toys or paper pulling mechanisms in printers.

Based on types of energy source, actuators are divided into following types.

- Pneumatic Actuator

- Hydraulic Actuator

- Electric Actuator

- Magnetic Actuator

- Mechanical Actuator

Pneumatic Actuator

A pneumatic actuator use compressed air or vacuum to generate forces. With a small pressure change, pneumatic actuators can generate a greater amount of force. This is the key benefit of a pneumatic actuator.

However, the pneumatic actuator’s energy loss can go up to 95% as you need to use a compressor and other sets of complex parts to create a vacuum or compressed air.

An example of pneumatic control is the car bonnet stunts.

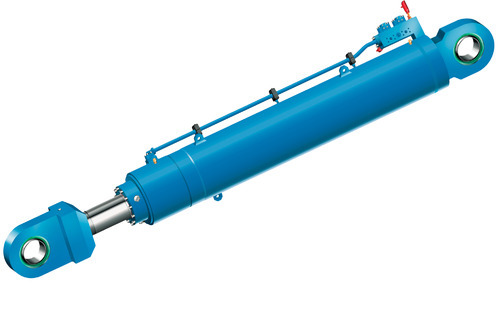

Hydraulic Actuator

Hydraulic actuators use fluids to create pressure. It is similar to how an engine generates power. Hydraulic Actuators need a cylinder, piston, and high viscosity fluid to create a force for converting the hydraulic pressure to mechanical motion.

Based on how pressure is applied, hydraulic Actuators can be classified into following two types

- Single-acting hydraulic actuator

- Double acting hydraulic actuator

When the fluid pressure is used on one side of the piston, it is called a single-acting hydraulic actuator. If the hydraulic pressure is applied on both sides of the piston, it is called a double-acting hydraulic actuator.

Hydraulic Actuators can create linear, rotational, and oscillating motion. An example of hydraulic Actuators is an automobile brake or clutch system.

Electric Actuator

Electrical actuators are a mechanical device that converts the electrical energy into linear motion. Some examples of electrical actuators are motor and linear motion solenoids.

Magnetic Actuator

Magnetic actuators use a magnetic field to generate mechanical motion and move objects. Electrical motors and solenoids are also an example of magnetic actuators. Magnetic actuators are devised into the following types.

- Moving coil actuator

- Moving magnet actuator

- Moving iron actuator

Mechanical Actuator

Mechanical actuators do not have an automated energy source, which means you have to apply manual force to actuate it. In other words, mechanical actuators convert one type of motion to another by utilizing pulley, gear, chains, etc. For example, manual steering, shutter door, etc.

Application of actuators

Actuators are used almost everywhere where automation is used. Not only in commercial products but actuators are also in household appliances as well.

In Automobile Industry

- Door locking mechanism

- Power window

- Throttle mechanism

- Car bonnet control

- Automatic rear door opening

- Automatic seat height adjustment

In Medical Industry

- Ventilator

- Dental chairs

- Hospital beds

- Incubators

- CT Scanner

- Laser positioning equipment

In Manufacturing Industry

- CNC machines

- NC machines

- Conveyors

- Assembly line automation

- Coolant head positioning

- Injection molding

- Robotic arm movement

- Automatic tape measurements

In FMCG Industry

- Remote controlled toys

- Automated refrigerator doors

- Automatic washing machine doors

- Printers

- Coin-operated washing machines

- Automated doors

Conclusion

I hope you got a basic idea about what is called actuators and what they actually do. As I said that actuators become very common nowadays as, without actuators, automation is almost impossible.

If you have any questions on actuators or want to learn more about actuators, please write in the comment section and I would love to solve your queries.

You may also like to read:

1. Types Of CNC machines

2. Two plate mold vs three plate mold