Rake angle is a very critical parameter used in many cutting and machining processes to describe the angle of the cutting face of the tool to the face of the workpiece. In this article, we will learn more about Rake angles, their importance, and the types of rake angles.

What Is Rake Angle?

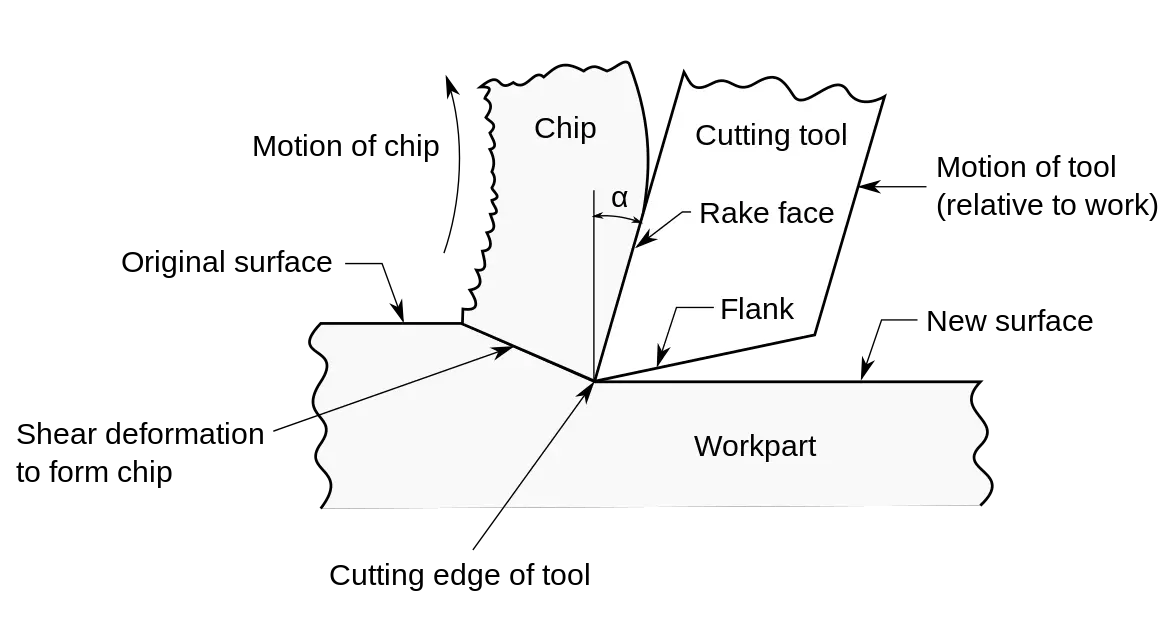

It is the angle that the rake surface of the tool makes with a reference plane. A reference plane is a plane that is perpendicular to any point on the cutting tool’s cutting velocity vector.

The cutting tool’s rake must be checked and controlled to ensure proper machining. Even so, it can be hard to measure rake angle with common tools.

The rake angle is very important for the proper flow of different types of chips that are produced during a matching operation.

Importance of Rake Angle

The rake Angle is a very important parameter that we need to consider while designing a tool. A couple of reasons are listed below.

- The cutting resistance increases or decreases based on the rake angle.

- It changes the amount of force needed to cut the metal and the amount of energy required.

- The rake angle ensures a smooth flow of metal chips during a machining operation.

- The rake angle decides if you will get a smooth or a rough surface on the workpiece.

Types of Rake Angle

There are different types of Rake angles as outlined below. The rake angle is mainly decided based on the following parameters like cut depth, workpiece material, machine RPM, etc.

- Positive Rake Angle

- Zero Rake Angle

- Negative Rake Angle

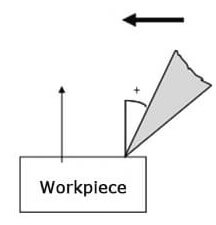

Positive Rake Angle

When the rake angle is positive, the clearance angle plus the wedge angle add up to less than 90 degrees. With a positive rake angle, the cutting edge is sharp, so there is less chip deformation when machining. With this cutting tool, you need less cutting force and power.

It also makes it easier to machine by reducing heat production during machining by a large amount. If the material of the workpiece is malleable and soft, and if continuous chip generation is desired, a cutting tool with a positive rake angle will be most effective.

Credit: Ukocarbide

Advantages of Positive Rake Angle

- Less cutting force is required when you use a cutting tool with a positive rake angle.

- If the cutting tool has a positive rake angle, the built-up edge breaks down fast and flows away with the metal chip.

- A positive rake angle reduces machining temperature.

- A positive rake angle ensures chip formation continuously and the flow of chips is smooth

- Positive rake angle increases machining productivity

Disadvantages of Positive Rake Angle:

- A positive rake angle lowers the wedge angle, reducing tool tip strength. It limits the cutting tool’s ability to resist higher cutting force and absorb more heat during machining.

- Positive rake angle tools wear out quickly, especially flank wear.

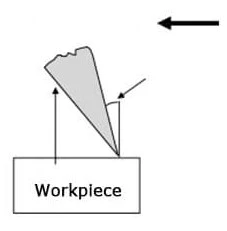

Negative Rake Angle

A tool has a negative rake angle when the face of the cutting tool slopes away from the cutting edge at the outer side. A negative rake angle is required when machining hard and tough metals like titanium, steel, etc.

Tools with a negative rake angle have a strong tooltip and thus can withstand more impact loading. It can also resist plastic deformation. So your tool life will be more if it has a negative rake angle.

However, the biggest problem with the Negative Rake Angle is that it does not produce continuous metal chips which are really bad for machinability.

Credit: Ukocarbide

Advantages of Negative Rake Angle:

- A larger wedge angle makes the tooltip sturdy enough to withstand higher feed and depth of cut. Thus, such a tool can increase the material removal rate without decreasing tool life.

- A tool with a negative rake angle lasts longer.

- A negative rake tool can improve material removal rate and productivity by increasing feed rate and depth of cut.

- Old machines vibrate due to worn parts and loose joints. Negative rake-cutting tools absorb impact loads for such machines and last longer under mild vibration.

Disadvantages of Negative Rake Angle:

- A negative rake increases normal force and decreases frictional force. During machining, it can deflect and vibrate tools.

- Chip material deforms significantly during shearing, causing various problems for the tool and workpiece.

- Shear deformation increases chip thickness and chip reduction coefficient, which increases cutting force and power consumption.

- The built-up edge will remain on the tooltip longer due to lower frictional force.

- A lot of heat is generated during machining. So you may need a cooling mechanism in place when using a tool with a negative rake angle.

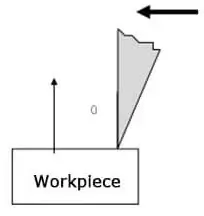

Zero Rake Angle

With a zero rake angle, the rake surface of the tool becomes flat when it intersects with the reference plane.

When the rake angle is positive, the strength of the tooltip is diminished because the wedge angle is decreased. When the rake angle is negative, the tool tip gets strong, but the more cutting force is required due to higher shear deformation. A tool with zero angles sits between the two and solves the problems of both positive and negative rake angles.

Credit: Ukocarbide

Advantages of Zero Rake Angle

- It makes the tooltip stronger and makes the tool last longer than a positive rake tool.

- Compared to a negative rake tool, it makes cutting easier by reducing chip thickness, cutting force, cutting temperature, etc.

- It uses less power than a negative rake tool because it cuts down on the force needed to cut.

Disadvantages of Zero Rake Angle

- In this type of tool, the built-up edge is formed.

- The efficiency of the cutting operation is poor.

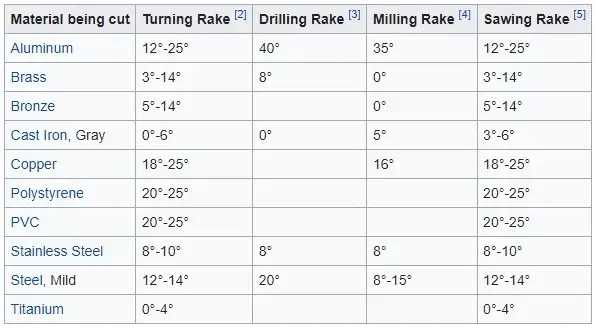

Recommended Rake Angle For Different Materials

Below is the recommended rake angle of a tool for single-point turning on a lathe, drilling or milling operation.

Conclusion: Types Of Rake Angles

The rake angle is an essential part of tool geometry. Choosing the right rake angle improves the overall efficiency and cost-effectiveness of cutting. There are three different types of rake angles, positive rake angle, negative rake angle, and zero rake angle. The recommended rake angle depends on the tool material, the material to be cut, and the speed and depth of cutting.