If you are working in the sheet metal industry then you might be aware of CRCA and HECA sheets. These are the two common types of sheet metal used in the fabrication industry.

However, many of us may not be aware of the difference between CRCA vs HRCA sheet. So let us learn in this article about the difference between CRCA and HECA sheets. But first of all, we should understand what the rolling process is.

What is rolling process?

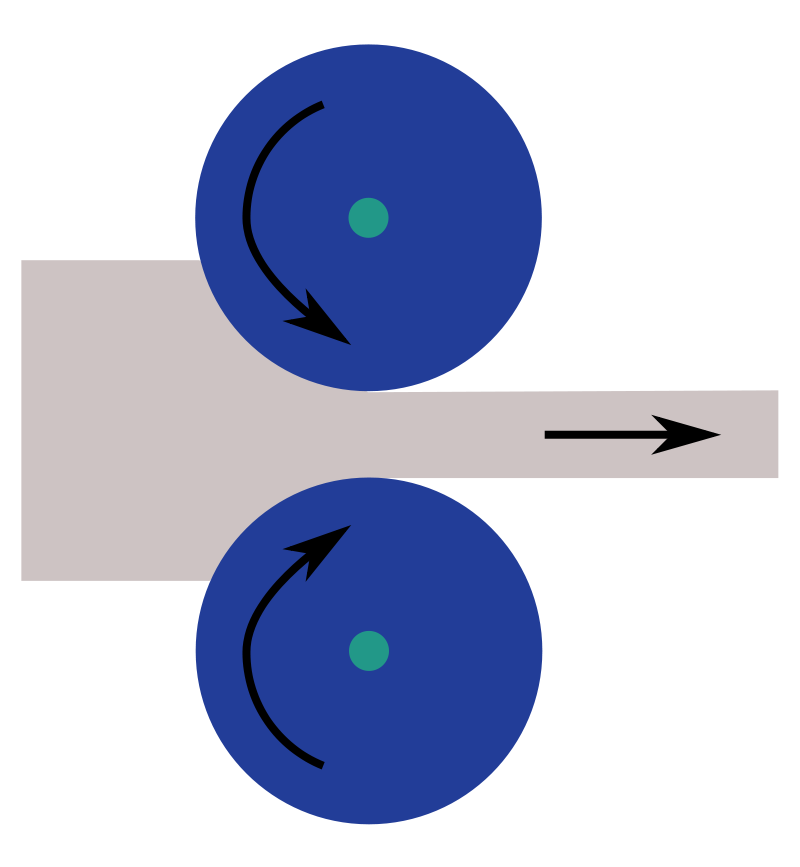

Rolling is a metalworking process in which metal sheets pass through many rollers to get a reduced and uniform thickness.

Rolling happens when the metal sheet reaches the plastic state and rolling is only possible if the metal sheet is ductile. Harder and brittle material is difficult to roll.

Rolling can be done either in-room temperature or in an elevated temperature environment. If the rolling is done at room temperature, then the material is rolled below its recrystallization temperature. This is called cold rolling.

If the metal is rolled above its recrystallization temperature, then it is called hot rolling. After the cold rolling or rolling, metal is annealed in a close chamber with a nitrogen environment and with nonoxidizing gases. This annealing process makes the metal softer for commercial applications. Annealing also helps in making sheet anti-corrosion up to some extent.

After the annealing process, oil and different chemical layer are applied on the surface of the sheet so they are resistant to corrosion. But in reality, they are not 100% corrosion resistant. You need other methods like powder coating to make those end products 100% corrosion resistant.

Both process has its advantages and disadvantages which we will discuss in this article.

Cold Rolled Close Annealed Sheet ( CRCA)

A cold rolled close annealed ( CRCA) sheet is cold-rolled sheet metal. As I said that these cold rolled sheets are rolled under recrystallization temperature which is usually 50-degree Celcius. The carbon content is usually low in the CRCA sheet as the composition is not altered by heating.

Cold-rolled sheets are much harder and finishes are much better than hot rolled steel. Also, the achieved dimensional accuracy is good since there is no heating of the material.

The surface of the cold-rolled close annealed sheet is of smooth blue-gray finish with square corners. Since there is no heating, dimensional accuracy is very high, and that is why you may get sheets of less than .01 inch thickness also.

Example of uses of CRCA sheets are enclosures, automotive doors or body, computer case, furniture etc.

Types of CRCA sheet: CRCA sheet grades

Commercially CRCA sheets are categorized based on the carbon content and how easily those can be drawn. If the carbon content is less, then it is easier to draw into shapes. Below are the main four types of CRCA sheets used in industries.

- Ordinary ( Carbon Content- .15%)

- Drawing ( Carbon Content -.12%)

- Deep Drawing ( Carbon Content – .10 %)

- Extra Deep Drawing ( Carbon Content – .08%)

You may also like to read: Types Of Heat Treatment

Hot Rolled Close Annealed Sheet ( HRCA)

Hot rolled close annealed sheets are rolled above its recrystallization temperature which is usually 1000 degrees Celcius. During heating, the metal goes through different stages. Due to this, the properties of the metal are also get altered.

Dimensional accuracy and surface finish are poor in hot rolled steel. Hot rolled steel is usually softer compare to cold rolled steel due to heating. Due to poor surface finish, HRCA sheets are not used in precision parts.

One more issue with the HRCA sheet is that, when it is cooled after heating, it changes the size and shape due to shrinking. This is one more reason HRCA sheet is not used in applications where higher dimensional accuracy is expected.

A typical example of uses of HRCA sheet is in bus floor or train floor.

If the sheet thickness is below 6 mm, then it is called a sheet, Anything beyond 6 mm thickness is called blocks. This is a traditional industry practice.

Difference between CRCA vs HRCA

| CRCA | HRCA |

|---|---|

| CRCA is a cold rolled sheet | HRCA is a hot rolled sheet |

| Metal is rolled below recrystallization temparature | Metal is rolled above recrystallization temparature |

| Sheets are harder | Sheets are softer |

| Very smooth surface | Rough sheet surface |

| Good dimensional accuracy possible | Poor dimensional accuracy |

| No change is chemical composition | Chemical composition may get change |

| Very thin sheets are available | Thin sheets are not possible. |

| Suitable for precision parts | Noy suitable for precision parts |

| Sheets are costly | Relatively cheaper |

| Used in almost every industries | Very limited application |

You may also like to read: Types Of CNC machine

Conclusion: Cold Rolled Close Annealed vs Hot Rolled Close Annealed

I hope this short article on close rolled close annealed vs shot rolled close annealed sheets could able give you a basic idea about the differences. Most of the industries use CRCA sheets only except there are specific requirements. CRCA sheets are also easy to form to different shapes.

If you have any questions or want to suggest anything, please do write in the comment section and I will be happy to respond. Below I share a very nice video on this topic. Video credit goes to Metal Supermarket YouTube Channel.

Frequently Asked Questions(FAQ)

Why close annealing is done on rolled sheet metal?

Annealing is done in a closed nitrogen chamber to soften the metal and also to make it corrosion resistant up to some extent.

What is CRCA sheet?

CRCA means Cold rolled close annealed. So sheets produced by this method is called CRCA sheet

What is HRCA sheet?

HRCA means Hot rolled close annealed. So sheet produced by this method is called CRCA sheet

Which sheet metal is widely used . CRCA or HRCA?

CRCA

What are different types of CRCA sheet

Ordinary

Draw

Deep draw

Extra Deep draw