Venturimeter is a key instrument in the Mechanical engineering field, especially in Fluid Mechanics, to measure the flow rate of fluids inside a pipe. It is widely used in the water, chemical, oil, and gas industries. Unfortunately, many of us know a little about Venturi Meter. So in this article will talk about Venturimeter, its advantages, disadvantages, and the working principle.

The Venturimeter is called after GB Venturi, who developed the concept of Venturimeter in 1797; however, this concept got into practical consideration by Clemens Herschel.

Venturi meter Definition

Venturimeter is an instrument used to measure the speed and flow rate or discharge of liquids through a pipe. In the venturi meter, the pressure energy is converted to kinetic energy. The Venturimeter working principle is based on Bernoulli’s theorem.

When fluid passes through different cross-sections of a venturi meter, it undergoes different levels of strain. This strain difference is measured with the assist of a manometer, which helps determine the rate of fluid flow through the pipe.

Key Parts Of Venturimeter

There are mainly three parts of venturi meter

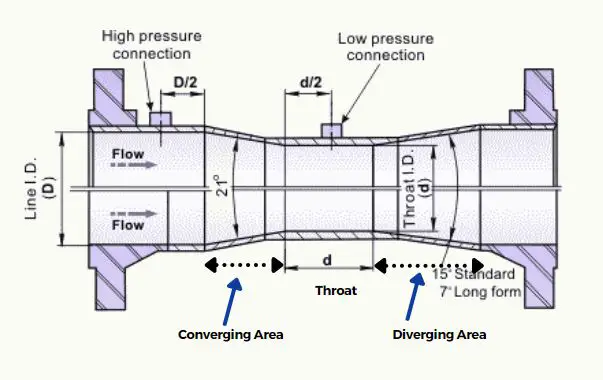

- Conical Converging Area

- Cylindrical Throat

- Conical Diverging Area

Apart from that there are two cylindrical entry and exit area which is called Entry Main & Exit Main

Conical Converging Area

After the inlet main, the converging area starts. In the converging area, the diameter gradually decreases because the flow rate increases at the cost of pressure loss.

The converging angle is 20-22 degrees, and the length of the converging area is about 2.7 Dd. Where D is the diameter of the inlet main and d is the diameter of the throat.

Cylindrical Throat

The throat is the central part of the Venturimeter and its cross-sectional area constant. The throat is the area where the venturimeter has the least diameter. The pressure is at the lowest point and the velocity is at the highest inside the throat.

One end is connected with the converging area, and the other end is connected with the divergent area. The throat diameter is 1/3 to 1/4 of the diameter of the inlet area.

Conical Diverging Area

This is the last section of the venturi meter where the cross-section area gradually increases. Due to that, the pressure is built up again, and the velocity starts decreasing. The typical conical angle in the diverging area is about 7-15 degrees.

Derivation Of Venturimeter

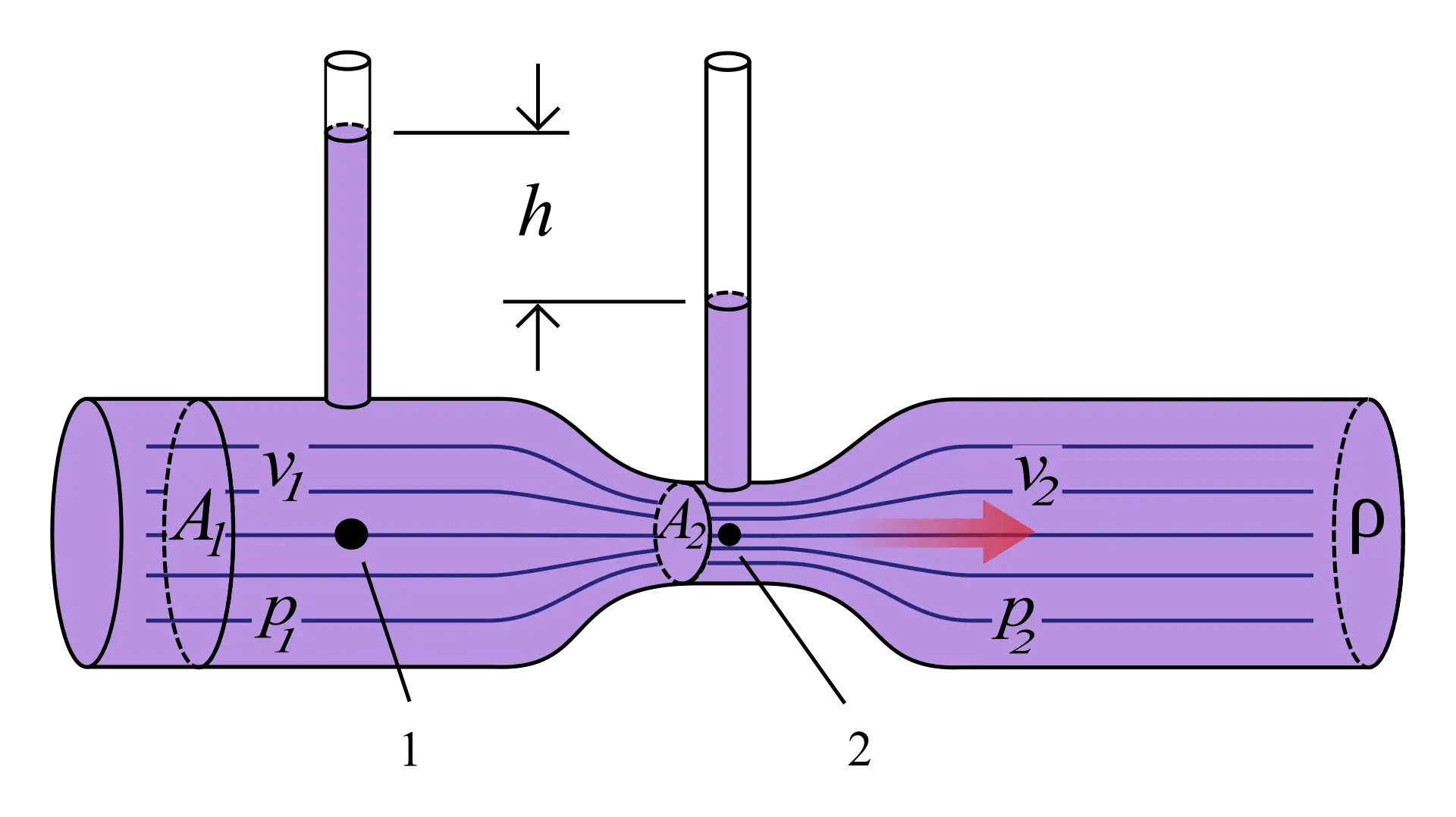

P1 = Pressure at the cylindrical inlet section

p2 = Pressure at Throat section

v1= Velocity of fluid at the cylindrical inlet section

v2= Velocity of fluid at the throat

a1= Area of the cylindrical inlet section

a2= Area of the throat section

ρ = Density of the fluid

g = Gravitational constant

Now at both sections if we apply Bernoulli’s theorem, then

(p1/ρg)+(v12/2g)=(p2/ρg}+(v22/2g)

(p1-p2)/ρg = (v22-v12)/2g

h = (v22-v12)/2g

Where,

(P1-P2) / ρg = h = Difference of strain head at the cylindrical inlet section and the throat.

Now Let us apply the continuity equation.

a1v1 = a2v2

v1= (a2v2)/ a1

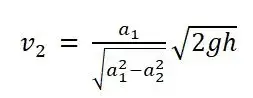

Now let us apply the value of v1 to calculate the strain head.

h= v22-[{(a2v2)/ (a1)}2]/2g

Now from this equation we get the value of v2

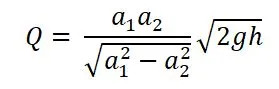

Discharge Q= a2v2

Substitute value of v2 in the above equation

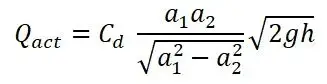

Q is the theoretical discharge under ideal conditions. The actual discharge formula is given by

Where Cd is the co-efficient of the Venturimeter, and its value is less than 1. We apply the co-officiant of discharge to calculate the actual discharge because due to the friction between the venturi meter surface and the fluid, there will always be a pressure and velocity loss.

What is Co-Officiant Of Discharge?

Co-Officiant of discharge of venturimeter can be calculated as the ratio of actual flow rate to the theoretical flow rate.

Cd=Qact/Q

Where Cd= Co-Officiant of discharge

Qact= Actual flow rate

Q= Theoretical flow rate

The value of co-officiant of discharge lies between 0.95-0.99. However, if you want to achieve a higher Co-officiant of discharge, then you need to smoothen the surface of venturimeter. ISO 5167 is the standard that provides the values of various co-officiant of discharge.

Working Principle Of Venturimeter

Let us consider the two cross-sections of a typical venturimeter , one at the inlet and the other at the throat. The difference in the pressure heads of these areas is used to calculate the rate of flow through the Venturimeter.

As soon as the water enters the inlet area, that is, it goes through the convergent area and reaches to the throat.

The throat has a smaller cross-section area, and in fact, it has the smallest cross-section area in the Ventrimator as the water enters the throat, fluid velocity increases, and the pressure decrease to a minimum due to the increase in velocity.

Now there is a pressure difference of the fluid in the two sections. In Section 1 (i.e., at the inlet), fluid pressure is maximum, and velocity is minimum. And in Section 2 (throat), the velocity of the fluid is maximum, and the pressure is minimum.

The pressure difference between the two sections can be seen in the manometer fitted in both sections. And then, we can use Bernoulli’s theorem. And the continuity equation to find out the value of discharge.

Types Of Venturimeter

There are three types of venturimeter available in the market.

- Horizontal Venturimeter

- Vertical Venturimeter

- Inclined Venturimeter

Advantages of Venturimeter

- Venturimeter provides accurate results.

- The accuracy of the Venturimeter is not dependent on the temperature and pressure inside the pipe.

- Very little energy loss.

- Wide applicability to water, suspended solids, gases, slurries, chemicals, dirty liquids, etc.

- High discharge coefficient and very low-pressure drop.

- Venturi meters may be established in a horizontal, inclined, or vertical direction.

- The pressure recovery of the Venturimeter is very high. The discharge pressure is almost near the inlet pressure.

- No moving part

Disadvantages Of venturimeter

- They are large and therefore, where space is limited, they cannot be used.

- The initial cost and installation cost is high

- A longer placement length is required. That is, the venturimeter must be operated by a straight tube with no connections or misalignments to avoid flow disturbance for satisfactory operation.

- It cannot be used in pipes with a diameter of less than 7.5 cm.

- Maintenance is not easy.

- It cannot be modified to measure pressure beyond the maximum speed.

Application Of Venturimeter

- In industries, venturimeter is used to measure the flow rate of gas

- In medical industries, venturimeter is used to measure the blood flow rate

- In a water treatment plant, venturimeter is used to measure the pressure difference and the discharge of water.

- In engine carburetors, venturimeter is used to measure the airflow.

Conclusion : Venturimeter

Although we may see many electronic devices to measure the flow rate and pressure drop inside a pipe, still venturi meters are widely used in industries. The precision level may not be as high as expected. But it is easy to use and can be used in a wide array of applications. The cost is also low compared to any modern electronic device that measures fluid discharge and pressure loss.

That’s all we have in this article. If you have any questions or queries, then you are always welcome to write in the comment section, and I will be happy to help.

You may also like to read: Difference between jigs and fixture