The demand for EVs is at an all-time high now. Since EVs don’t have an engine or drivetrain, it becomes more important to implement a smart management system to control how a battery behaves, as the battery is the heart of an electric vehicle.

Since the battery and the motor are the key components of an electric vehicle, things get smoother to control their operation at the component level.

That is where the Battery Management System In Electric Vehicles comes into play. In this article, we will learn more about it.

What Is A Battery Electric Vehicle?

A battery-electric vehicle or all-electric vehicle uses a motor to propel the wheels. The motors get power from a battery. Electric vehicles do not have an internal combustion engine or a drivetrain.

In electric vehicles, chemical energy is converted into mechanical energy. Batteries store the energy and transfer it to the motor when needed.

Depending on the requirements, different sizes, types, and capacities of batteries are used.

Lithium-ion batteries are most common in electric vehicles due to their high energy density (100-265 Wh/kg).

A high-capacity battery pack can be constructed in a limited space. Due to its compact size, it is most suitable for electric vehicles.

But that opens loopholes to safety. Due to their compact size and high energy density, lithium-ion battery packs are notorious for being heat—and fire-hazardous.

A smart battery management system for electric vehicles is essential to run electric vehicles within safety limits.

Battery Management System In Electric Vehicles

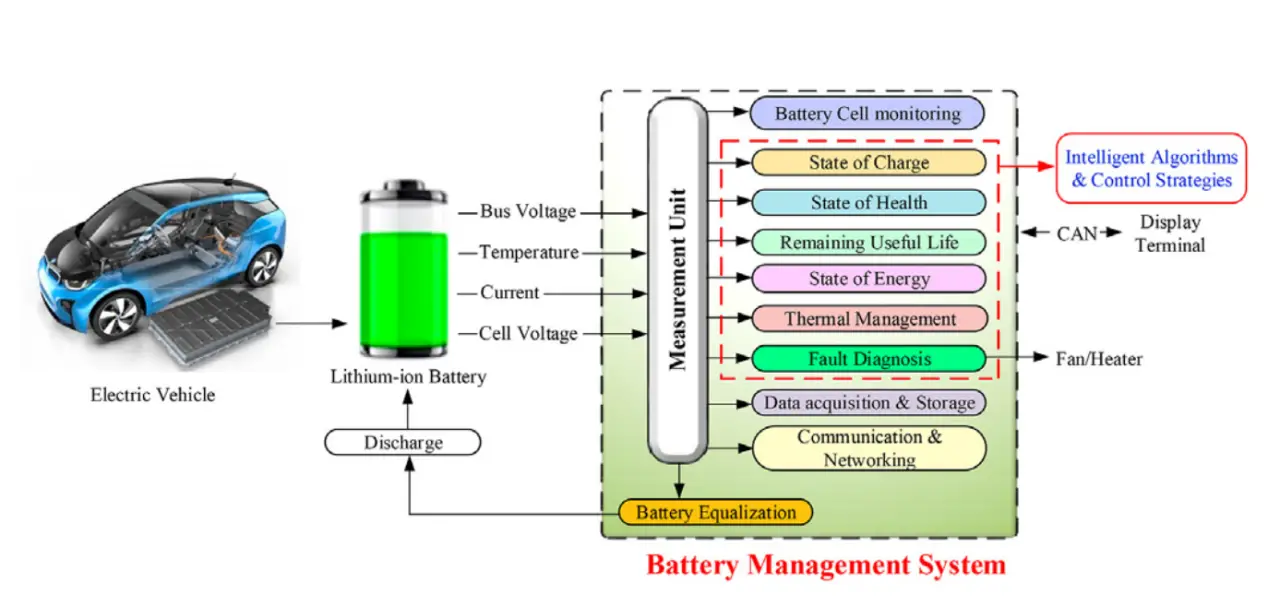

EV Battery Management Systems ( BMS ) manage the electronics of a cell or a battery pack so that they can work under safe operational parameters. They ensure that both the battery and the user are working within safe limits.

It can monitor the battery’s State Of Health (SOH) data and adjust different parameters accordingly to ensure that the battery is working under a safe voltage limit and that there are no thermal or fire hazards.

The BMS system also ensures the battery’s long-term health by controlling its operational usage and cell balancing.

BMS is also responsible for charging control, overcharge protection, overheating protection, and short circuit protection.

It can also connect with external sensors to provide real-time data on State Of Charge, Range, and Voltage.

Key Functions Of BMS In Electric Vehicles

The Battery Management System does many jobs apart from the safety of the battery, which is its primary job. Here are some of the key functions of BMS

Monitor Battery Parameters

Monitoring battery parameters is one of BMS’s primary jobs. Here are some of the parameters that BMS monitors.

Remember, these are just key parameters. A BMS can also show other relevant data, depending on how it is programmed.

- Voltage: Shows the battery pack’s combined voltage and maximum and minimum voltage attained by the battery pack

- Temperature: This shows the average cell temperature, coolant intake and output temperatures, and the overall battery temperature.

- State Of Charge (SOC): It is the charging level indicator that shows on the instrument panel

- State Of Health (SOH): Shows the battery’s overall health. SOH decreases over time

- State Of Safety (SOS): This indicates if the battery is in danger. It could be a warning or error.

- State Of Power (SOP): This shows the average cell temperature, coolant intake and output temperatures, and the overall battery temperature.

Making Key Calculations

Yes, BMS can also do some key calculations and display the data that can tell how the battery is operating, at what capacity it is, what the efficiency is, and other relevant data.

- Energy: It shows the delivered energy in kWh since the last charge

- Impedance: Shows the internal state of health of battery cells

- Charge in Ampere per hour (Ah): Shows the charge in Ampere per hour (Ah) delivered or contained in a cell, to determine the cell’s efficiency

- The total number of charge cycles that the battery has gone through

Thermal Management

Heat is the main enemy of batteries. Due to the compactness of lithium-ion batteries and how cells are contained in the battery pack, they are very fragile due to temperature differences.

Due to this, the battery management system works hard to keep the battery temperature under control.

For example, when an electric vehicle runs at a very high speed, it consumes a lot of energy and thus increases the battery pack’s temperature.

The battery management system can automatically reduce the speed or even turn off the vehicle to control the temperature.

All vehicles have a passive thermal management system, which is either air-cooled or liquid-cooled.

However, when this passive thermal management system is used, the battery capacity degrades because the battery consumes a significant amount of energy to run these systems.

The BMS can also manage when and how that coolant should flow and how it should flow. Ultimately, the BMS decides what to do to keep the battery temperature in control.

Optimize Battery Utilization

One key job of a BMS is to optimize the battery charge so that the vehicle gets the maximum range per charge without compromising on the required power.

That is why electric vehicles have different modes. Different modes consume different amounts of battery charge and deliver different levels of power.

Conclusion: Battery Management System In Electric Vehicles (EV BMS)

The Battery Management System is a key component in electric vehicles. It is the brain of the vehicle, deciding how to use the battery efficiently without compromising the power and safety of the battery pack.

It can monitor and control most of the vehicle parameters to ensure the safety of the battery and the user.