In the sheet metal fabrication industry, blanking, piercing, and punching are very common operations. For a newbie, all those operations may feel the same. But there is some difference between blanking and piercing and punching. So in this article, we will talk about the differences between these three major sheet metal operations.

What Is Sheet Metal Fabrication Process?

All three operations listed in this article comes under the sheet metal fabrication process. So having a basic idea about the sheet metal fabrication process is important before we jump into Blanking, Piercing, and punching.

Sheet metal fabrication is a metalworking process to cut and form sheet metal into the desired shape which can be useful for end applications. There are two main operations of the sheet metal fabrication process. One is Cutting and the other is Bending

Blanking, Piercing, and Punching comes under sheet metal cutting operations. The tooling for all three operations is almost the same, however, the size and shape can be different. The reason for using different terminology is to differentiate between what we call a finished part and what we call a scrap. This concept will be discussed later in this article.

Cutting in sheet metal can be done either by thermal operation or mechanical operation. The thermal operation basically includes laser cutting and plasma cutting and mechanical cutting basically includes Blanking, shearing, Piercing, and Punching. However, the list of operations is not at all exclusive and there are many other mechanical cutting operations for sheet metals.

Must Read: Difference between CRCA and HRCA sheet

How does sheet metal fabrication work?

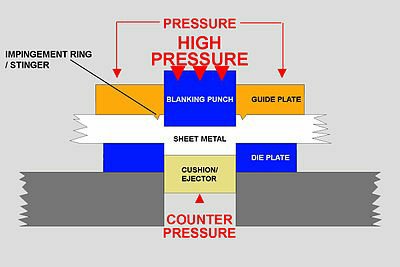

For sheet metal fabrication we need a tool usually made of hardened steel or tungsten carbide. We also need a die that will be placed opposite the tool. Die acts as a cavity and the punch tool act as a core. In between punch tool and die, the workpiece ( sheet metal piece) is placed.

When the Punch tool is pressed against the die, the workpiece in between gets deformed as it goes into the plastic state due to the force. There has to be a vertical gap between the tool and die which we call tool clearance.

That clearance has to be more than sheet thickness. Depends on sheet metal, burrs can be formed on the opposite side of the tool movement. A secondary operation is required to remove those burrs.

Shearing

Shearing is a sheet metal cutting operation in which small workpiece is cut from a raw sheet metal coil supplied by manufacturers.

For example, let’s assume that you want a sheet metal piece of size 500 mm X 500 mm. Usually, in India, raw sheet metal suppliers supply sheets having a size of 1250 mm X 2500 mm or they supply in a coil form. So the process of getting a piece of 500 mm X 500 mm from that big raw sheet or coil is called shearing. The process and cutting mechanism are the same as explained above.

Blanking

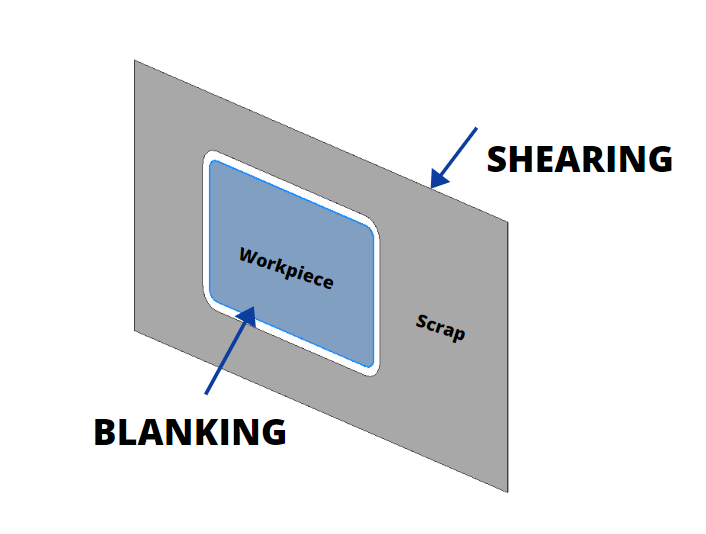

Blanking is also a sheet metal cutting operation through which you cut the desired flat sheet of an end part.

For example, in the below picture, the gray color part is the sheared part. From that, we are cutting a small piece of the metal piece which is the same size as our sheet metal parts flat pattern. So the blue color part is the blank.

Remember in blanking, the metal piece that is removed is the workpiece, and the piece that remains is the scrap.

Piercing

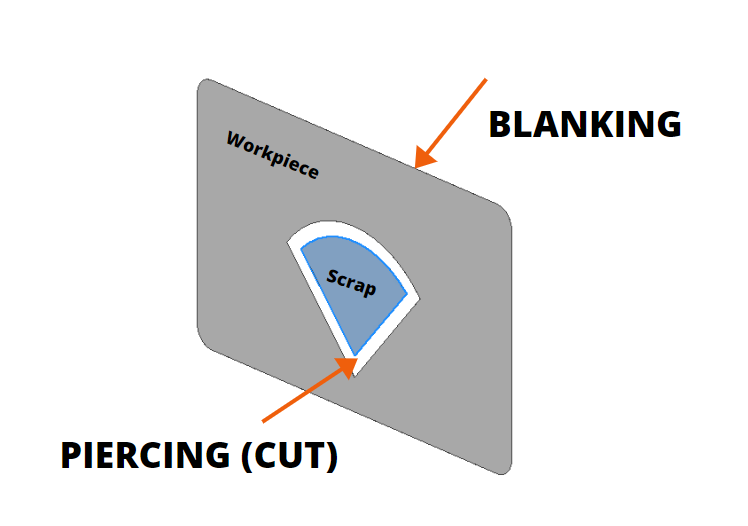

To understand piercing, let us assume that you want to make some cut-outs in the blanked sheet. After the cutout, metal pieces that remain are the workpiece, whereas the pieces that will fall from the machine are scraps. This phenomenon is exactly the opposite of blanking where the metal that remains is the scrap. Right?

So always remember that piercing is done only on the blanked sheet. Piercing process is depends on blanking operation.

There are different types of piercing operations used in industries. Below are few of those.

- Lancing

- Perforating

- Notching

- Nibbling

- Trimming

- Shaving

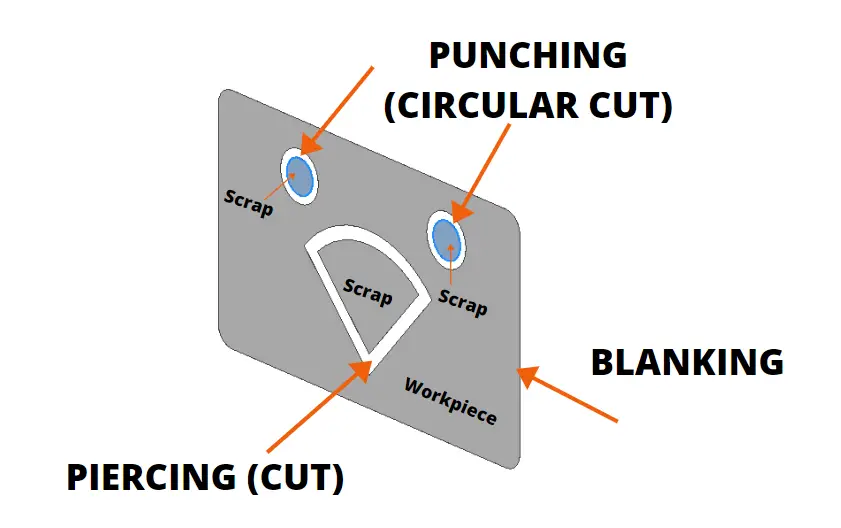

Punching

Punching can also be categorized as a piercing process, but the only difference is that punching is used for circular shape cuts. The tooling and process mechanism is the same as piercing.

So here is the typical workflow of any sheet metal part, no matter if the part is big or small.

Shearing— Blanking— Piercing / Punching— Bending —Deburr— Paining / coating

Conclusion

Shearing, blanking, piercing, and punching are the very basic and primary operations carried out in any sheet metal fabrication plant. The design trend is moving to sheet metal as it reduces part weight and offers the same strength as any solid metal part.

Personally, I designed many sheet metal parts from the casted part and this helped to reduce cost. I hope that this article could able to give you a basic idea about these basic sheet metal operations. There will be more articles on sheet metal in the future. But if you have any questions please do write in the comment section and I will be happy to reply.

Frequently Asked Questions (FAQ)

What is the difference between blanking and piercing?

In blanking, the left out material is scrap, whereas in piercing, the left out material is a workpiece. Both processes use the same sort of tooling, but only the terminology is different based on what we call workpiece and scrap.

What is the Difference Between Piercing and Punching?

Punching is basically making circular cutouts in sheet metal, whereas piercing is making cutouts of any shape. Punching has a set of over the shelf tool. For piercing, you need a customized tool.