When it comes to precise cuts, both CNC and laser cutting have high efficiency. Not only will this provide a user with desired results, but it will also help users save a considerable amount of time along with that. Both of these machines play a vital role for the workers working with steel or other metals.

Although both have the same purpose, there are few ways to differentiate them. One depends on the computer, and the other depends on heat energy. Before comparing these two, it is important to know what exactly each of these machines is. Let’s keep reading this article to find out the difference between laser cutting vs CNC cutting machines.

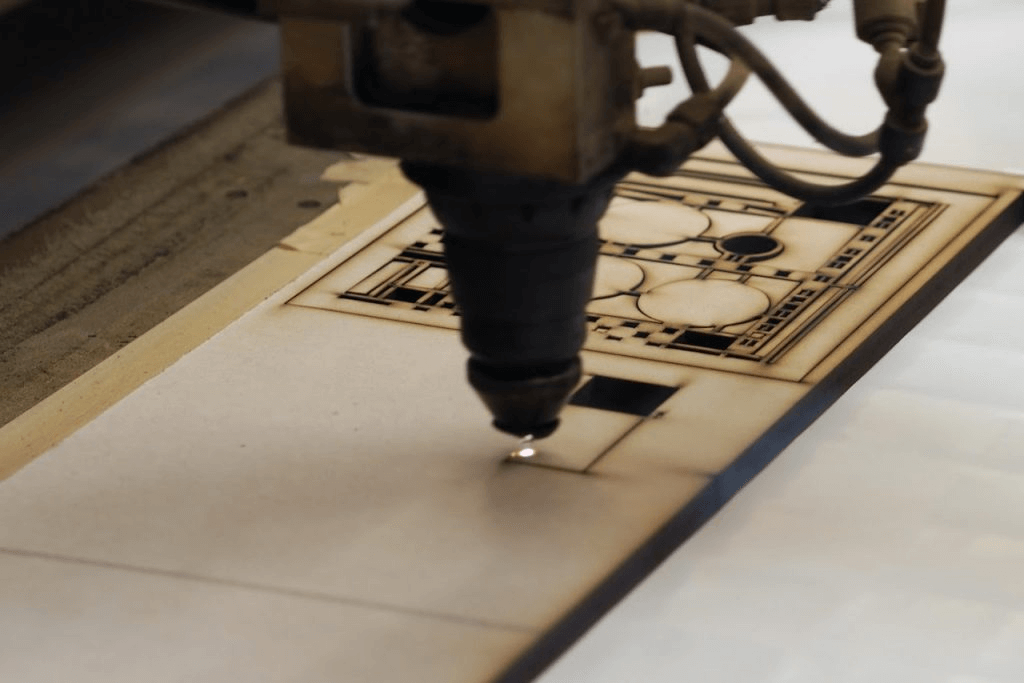

CNC Cutting Machine

CNC (Computer Numerical Control) is a cutting technique that uses a computer-controlled CNC router to cut things. Its most obvious characteristic is that it cuts through direct physical contact. Unlike most other cutting tools, the CNC cutting machine or CNC milling machine is automated and follows a set programmed path through computer numerical control. They can cut materials such as wood, aluminum, foam, gemstone, plastic, etc.

To use this machine to cut materials, the designers take ideas from customers to create the designs. After that, they draw the same design on a computer using a software program (AutoCAD or CorelDRAW). Getting the design accurate takes a lot of skill and is very time-consuming since the whole process is computer-oriented.

After the designers are done with the software work, they pass the instructions to the computer. It then sends CNC router a signal, and then the cutting according to the designs starts. The final results are always accurate, and there is zero material wastage.

CNC milling machines are generally used in automotive parts, electrical instruments, motorcycles, tools, hardware, and similar fields. There is a lot to learn about the types of CNC machines, parts, applications, and specifications.

If you are looking for a quick and reliable CNC cutting service then Pro Carve is one of the vendors then you can approach.

Laser Cutting Machine

Laser cutting machines possess the capability to cut materials by using a laser machine. This machine can be used to cut the same materials as a CNC cutting machine (i.e., glass, metal, gemstones, plastic foam, etc.). This machine is also computer-controlled, but the final cutting is done using a high-powered laser beam to make precise cuts by melting the created path made in the materials. This process is famous in industries because of its top-notch cuts and great outputs.

Laser cutting is most commonly used in automotive, mold, tool, jewelry, medical, and other similar fields.

Differences Between CNC Cutting and Laser Cutting

Even though both the process looks pretty much similar, few things differently. One of the most crucial differences between a CNC cutting machine and a laser cutting machine is that CNC cutting is achieved through friction, unlike laser cutting through heat. Here are some more differences between the CNC cutting method and the laser cutting method.

Cost Implications

One of the biggest advantages of a CNC cutting machine is that it is much more affordable, especially when compared to a laser cutting machine. The price of CNC cutting machines is one of the things that make industries prefer it more. The laser cutting machine itself is expensive, and the power consumption contributes to making it even costlier.

Suitability

Laser cutting machines are a great pick for welding purposes, unlike CNC cutting machines. Despite laser cutting machines having great features and positive exposure, there are still areas where CNC cutting machines stay to the fore. CNC cutting machine makes straight-line, diagonal, curved cuts incredibly easy as the machine is programmed to do the task.

Therefore, there’s no chance of human error. One might achieve creative cuts using laser cutters compared to CNC cutters, but if we compare the prices, CNC cutting machines are truly worth the price and results in perfect simpler cuts, making them perfect for industrial use.

Operational Expertise

A laser cutting machine is more advanced than a CNC cutting machine, and a fairly high degree of operational expertise is needed to handle it properly. On the other hand, a CNC cutting machine is much more straightforward and manual. Managing it does not require too much experience.

Precision

Laser cutting machines use a high-heat beam to pierce through items with ease. It is also easier to channel to the desired area. Hence, laser cutting machines are more precise when it comes to delivering a detailed, accurate outcome.

They provide high accuracy, and one will not need to provide extra physical effort to make sure everything is going correctly. But in the case of CNC cutting machines, constant moderation is a must.

Power Consumption

Both cutting machines need electrical power to operate, but the laser cutter machine demands higher levels of electrical energy. CNC cutting machines require a minimum power supply to run smoothly.

Cutting Speed

When all factors are considered, the laser cutting machine takes lesser time to do the cutting. CNC cutting machines take considerably longer due to the need to pierce the surfaces using cutting materials’ sharp blades.

Why Opt For Laser Cutting?

Laser cutting is indeed an expensive option. But if we consider the benefits that come along with that, it is indeed a great investment. This machine offers a level of precision that is not possible with friction-based cutting devices. Laser cutting machines provide more control while cutting, and users enjoy clean and sealed edges because laser cutting involves burning.

Why Opt For CNC Cutting?

One of the main reasons to opt for a CNC cutting machine is its affordability. Also, they are easy to operate, consume less power, and can cut diagonal, straight, or curved lines with a smooth-edged finish with ease. It is a great purchase for small businesses.

CNC milling machines from brands like Tsinfa can be of great use to provide premium quality machines at affordable prices. Users will also have plenty of CNC milling machines with different features to choose from.

Conclusion: Laser Cutting Vs CNC Cutting

Both CNC cutting machines and laser cutting machines are highly efficient and flexible for manufacturing industries. So, the decision must be taken after gaining sufficient knowledge about the features of both machines.

However, you will have to carry out routine and regular maintenance to ensure that coolants and the delivery systems deliver to expectations.

This is a guest post By Vincent Hua From the TSINFA team

Vincent Hua is the Marketing Manager at TSINFA. He is passionate about helping people understand high-end and complex manufacturing processes. Besides writing and contributing his insights, Vincent is very keen on technological innovation that helps build a highly precise and stable CNC Machinery.