Most of the engineering colleges nowadays have AutoCAD in their curriculum. So it is expected that you know about AutoCAD even if you are a fresher. Heading for your first job and you were asked: “ Do you Know SolidWorks”. Do you feel like what the heck is this SolidWorks? So in this article, we will discuss the Difference Between Autocad and Solidworks: Autocad vs Solidworks

It is unlikely that you will get an engineer who does not know about AutoCAD. In fact, AutoCAD is the first CAD software that was running in personal computers. It was the first software that brought the revolution to the CAD industry. People were reluctant to move away from traditional handmade drawing when AutoCAD started to shine.

Over time people started moving away from traditional 2D and that’s when SolidWorks was developed. SolidWorks is currently one of the best 3D CAD software, especially for Mechanical Engineers. It would not be unfair to say that nowadays you won’t find a single mechanical engineer who never used SolidWorks

AutoCAD

History Of AutoCAD

Many of us may not know that the concept of AutoCAD was originally developed by a company called Interact CAD. Autodesk bought Interact CAD in 1980 and launched the first version of AutoCAD in 1982

AutoCAD was the first CAD software that uses can install in their personal computers rather than microcomputers. Within a few months of launch, AutoCAD becomes a big hit and most of the industries started using it. Designers got relief from hand made drawings as AutoCAD has reduced the cycle time of creating drawings.

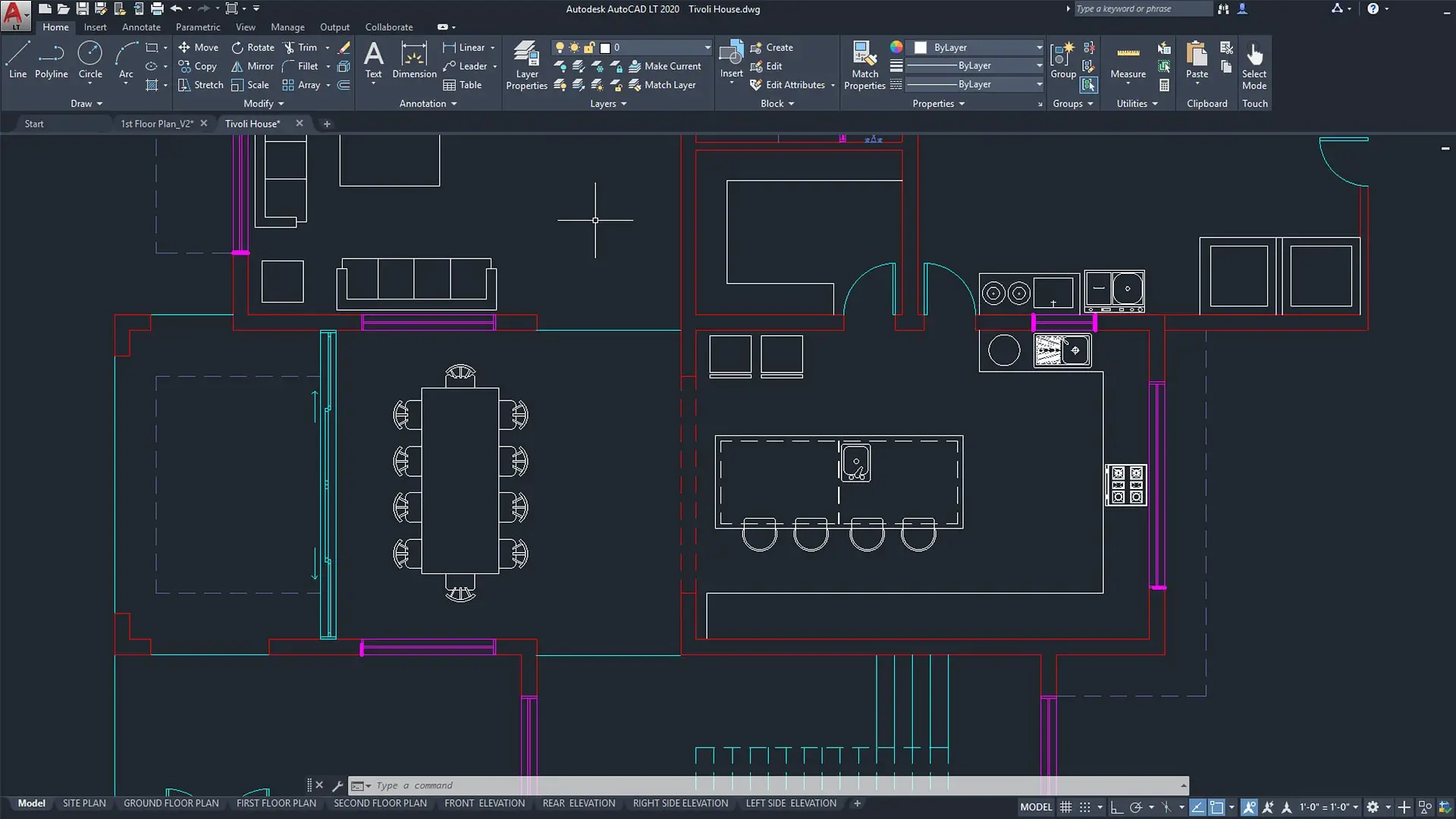

Over the years AutoCAD was revised many times, added many features but AutoCAD is still considered as a 2D CAD software. Autodesk also understands that and they always revamp the software to retain the title number one 2D CAD software. Presently there are many 2D and 3D CAD software but no software could beat the 2D CAD capabilities of AutoCAD.

Capabilities of AutoCAD

AutoCAD is primarily a 2D CAD software but over the years AutoDesk has added 3D CAD capabilities. Trust me, AutoCAD was never successful in capturing the 3D CAD market. The reason being AutoCAD was never serious about getting into 3D CAD. Creating a 3D model in AutoCAD is much tougher than any other 3D CAD software so people prefer to use it as 2D CAD software.

Though 2D CAD software is not in demand nowadays companies could not dump AutoCad. You know why? Because most of the CNC machine supports a .dxf file as an input and only AutoCAD can generate it. However many software nowadays can generate .dxf files but editing is very easy only in AutoCAD.

Pros Of AutoCAD

- Best software for 2D CAD

- Creating 2D CAD geometry is super easy

- No major technical knowledge is required to learn AutoCAD.

- AutoCAD generated .dxf file is still the preferred input file for modern CNC machines.

- AutoCAD can generate basic 3D models very easily.

- Industry-specific CAD customization is very easy using Autolisp.

- Forum based help is great as this is the oldest CAD software

Cons of AutoCAD

- Strickly a 2D CAD software.

- Creating a complex 3D model is super tough

- No assembly module is available.

- Industry trending modules like mechanism, animation, FEA is not present.

- No product data management tool.

Which industries use AutoCAD?

- The architecture engineering field uses AutoCAD as their preferred CAD software.

- Civil engineering projects find AutoCAD very easy to create layout drawings

- The electrical and electronics industry uses AutoCAD to design its logic board diagram and electrical routings.

- Map and GIS industry still uses as it’s super easy to work with.

- Basic mechanical engineering drawing can also be done easily with AutoCAD

To conclude I can say that every engineering industry uses AutoCAD or used AutoCAD in the past. It is the benchmark CAD software and many CAD software was developed based on it.

Suggested Read : Evolution Of CAD Software

SolidWorks

History Of SolidWorks

SolidWorks is a product of Dassault systems but do you know that the first version of SolidWorks was not developed by Dassault. Jon Hirschtick was an MIT graduate who started developing SolidWorks in 1993 along with his few friends. Soon in 1995, the first version of SolidWorks was launched.

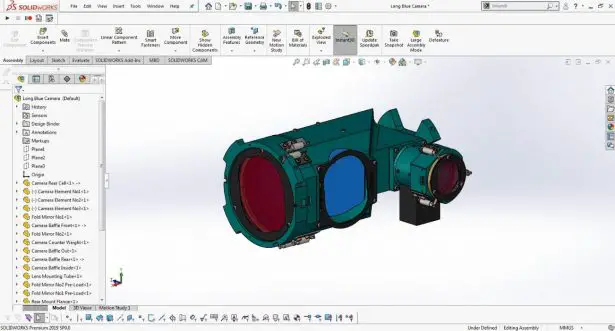

SolidWorks was an instant hit. It simply redefined the way people do 3D modeling. In 1995, 3D CAD software was not intuitive. SolidWorks was the first software that was intuitive as well as feature-rich. People just loved SolidWorks when it was launched.

In 1997, Dassault Systems bought SolidWorks although they had Catia in their portfolio. But Catia was serving a different market at that time. Merging with Dassault helped SolidWorks to increase customer base and within 2 years SolidWorks had a 3 million user base.

Over the year SolidWorks got revised multiple times and with every version, they improved the software capabilities. SolidWorks is one of the widely used software in the United States irrespective of the industry.

Capabilities Of SolidWorks

Frankly speaking, it would take multiple articles if I start writing about all capabilities of SolidWorks. Here I am writing only about a couple of key capabilities of SolidWorks which industries mostly use.

3D CAD modelling

SolidWorks is simply the best in 3D CAD modeling. It offers simple 3D modeling, surface modeling, free form modeling, etc. It also has the capability to do sheet metal modeling and wiring harness design.

2D CAD drafting

The 2D CAD drafting is different than AutoCAD in the sense that 2D CAD drafting in SolidWorks is mainly for parts and assemblies whereas in AutoCAD it can do anything. All 2D drafting in SolidWorks is parametric, what that means is that, if you make any change to the associated 3D model, the drawing auto gets updated.

Simulation

With SolidWorks, it’s easy to create a mechanism, animation, and simulation. These features help companies to validate the design before actual production.

Finite Element Analysis

SolidWorks is not only 3D CAD software. It does help to know how a physical part may behave under different loading conditions. It also helps to do thermal analysis which is a plus.

CAM ( Computer Aided Manufacturing)

SolidWorks has inbuilt capabilities to integrate with machines which we call computer-aided machining. SolidWorks is one of the best software for CAM

Electrical Design

This is one of the best software for electrical design or wire harness design. It has the capabilities of schematic design and 3D harness design

PDM ( Product Data Management)

Product data management tool is essential for keeping a records of a product life cycle. It helps to coordinate in multi user environment.

Pros of SolidWorks

- Best 3D CAD software

- Intuitive user interface

- Easy to use commands

- Smooth learning curve

- Easiest CAD software to learn

- Parametric CAD modeling

- Realistic 2D drafting

- Sheet Metal modeling

- Advanced assembly module

- Finite Element Analysis

- Mechanism and Simulation capability

- Product data management tools are available.

Cons of SolidWorks

- No cons except the fact that 2D CAD drafting is not as good as AutoCAD.

Which industries Use SolidWorks

Frankly speaking, SolidWorks is used by almost every industry. SolidWorks is such a versatile software to ignore. There is hardly any mechanical industry that does not use SolidWorks. But most of the industries that use SolidWorks are Medical Device, Home Appliances, Automotive, Aviation, and Heavy Machineries.

AutoCAD Vs SolidWorks

| AutoCAD | SolidWorks |

|---|---|

| Ideal for 2D Drafting | 2D drafting is not as good as AutoCAD |

| Basic 3D CAD functionalities | Advanced 3D CAD modelling is possible |

| No option for dedicated sheet metal modelling | It has sheet metal dedicated module |

| No option for rendering | Advanced rendering is possible |

| Part validation is not possible | Advanced part validation is available |

| Mechanism and animation command are not available | SolidWorks has dedicated module for mechanism and animation |

| No simulation module | Dedicated simulation module |

| Mainly used in architectural and civil engineering field | Mainly used for mechanical engineering field |

| No option for virtual reality | Module for virtual reality is available |

| Free student version is available | No free student version is available |

| Smooth learning curve | Steeper learning curve |

| Excellent user base | Moderate user base |

| No integration with CNC apart from saving file as .dxf | Dedicated module for computer aided manufacturing |

| Subscription based Licence | Term based licence |

| Licence price is very cheap | Too costly for individuals |

Conclusion

By now it is evident that there is a huge difference between AutoCAD vs Solidworks. Both serve all together with a different market and comparing both would not give a clear picture. Both software is the best in their respective field. Now it depends on you from which field you belong to.

If you are into civil engineering or architectural engineering then AutoCAD will be the tool that you should learn but for Mechanical Engineering it’s a must to learn SolidWorks.

I hope this article about AutoCAD vs Solidworks could help you to make a decision about which software you should prefer depending on your domain. If you have any questions please do let me know in the comment section.