The biggest duty of mining industries is for the maintenance and safety of all workers. An inspection door works as access toward the working site to perform the necessary assessment. It is also an entryway to clean the area inside the chute doors. With this door type, the maintenance process will be more at ease.

Is Inspection Door Installation Safe?

Safety is one of the top priorities of every workplace. This also applies to the installation of an inspection door on a certain site.

There are recorded incidents in the past that were caused by not having safer access like that of an inspection door type. It results in injuries and even death in the worst scenarios.

Therefore, adding an inspection door for example in mine sites will also enhance safety. It reduces the chance of workplace accidents and also the cost for damages by the business.

Some other things about this door type will be discussed in this post. So, keep on scrolling.

Inspection Door Types?

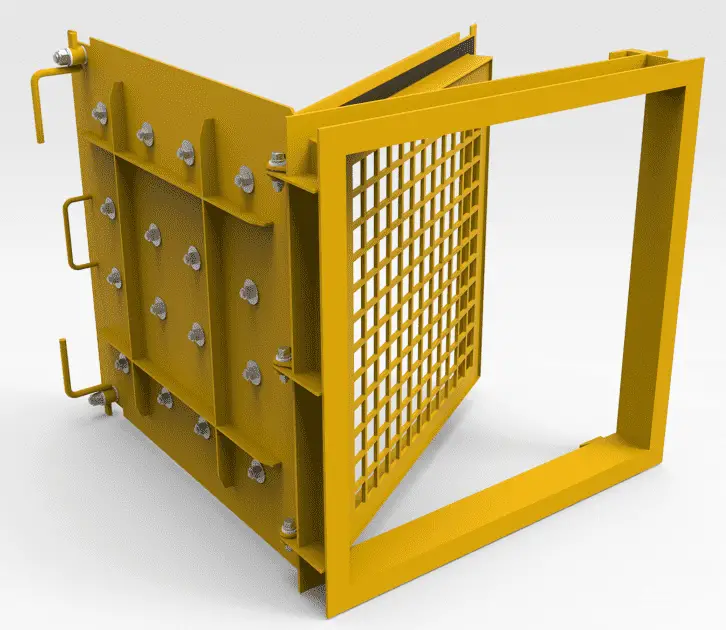

The inspection door has three parts that promote different levels of safety. It includes:

- Outer Door: This is the first layer of safety that is visible outside the workplace. It has a rubber seal for soundproofing and added protection. At this point, the operator has no access to the chute because a second door exists.

- Second Door: This part is similar to jail doors made up of durable bars. It is positioned at the center to prevent possible hazards.

- The operator can only view the area but still has no access to the chute. This adds up safety for the workers to monitor the area first before entering in.

- Cross Bar System: The last layer of protection is an effective defense against chute door incidents. It has a bar structure to avoid personal access to the chute.

Furthermore, some inspection doors require a mechanic tool to open. The level of security is high and only authorized personnel have the right to operate the entryway.

It can never be opened by hand but still consumes time, especially if the bolts are already rusted.

Features to Look For In Inspection Door

Since inspection doors are responsible for safety, then look at their key features for a worthy investment. It includes:

Durability

Inspection doors are made of thick metal for improved security. It safeguards the workplace from the risk of falling debris for a very long time. Only selected staff can have access to the chute which is the best thing about this access point.

Design

Most chute doors have a modular design for easy replacement. It can be replaced without modifying the chute cavity but by only installing a new door. It must not compromise the seal’s durability to prevent debris from entering in.

Weather Resistant

Find an inspection door that can withstand both high and low temperatures. This is to protect the chute from the effects of changing weather. The seal’s design has an impact on this feature so make sure it is stable and firm.

Locking System

A locking system plays a significant role in any door type. The operator must easily open the locks for every maintenance task so as not to miss out on anything.

However, it is also the weakest spot among the parts of the door, the same with the hinges. Locks can be subject to decay due to harsh weather so regular checkup is necessary for better performance.

Flexible

Mining sites have different needs, including the need for an inspection door. Many services can promise to install conveyor chutes but for a variety of purposes. Know the proper configuration of the door type before deciding to install one.

Easy to Open

It is said earlier that some chute doors require special tools to open. Nonetheless, this does not apply to all inspection doors.

Such a feature is an advantage during emergency maintenance by which the operator can open the outer door by hand. It won’t compromise safety as the door would not open accidentally.

Meets Safety Standards

If there is one most important factor an inspection door must have is compliance with safety requirements. Non-complaints may face a lot of liabilities when an accident occurs during the operation.

Availability

Looking for inspection doors can be difficult in times of replacement. Hence, try to find door models that are readily available at all times. This will reduce delays in installation and also limit overall operation shutdown.

Price

This type of door for mining sites is a great investment for safety. It may demand a higher cost but will last longer than cheaper options. It is also essential to look for a reliable door provider to perform the installation process for you.

Door Size

Last but not least, an inspection door is customizable in size. It depends on what size of a door will fit in the workplace.

First, you should measure the dimensions of the working site to get the exact door size. That being said, the overall performance of the door does not fully depend on its size.

Best Recommended Inspection Door Provider

Installing conveyor inspection doors is not an easy job as it reflects the safety level of a mining site. There is a wide range of inspection doors to choose from depending on the workplace.

Experts know what is most suitable for a certain worksite and they will be responsible for delivering the best results.

Get in touch with the nearest inspection door provider in your place to start the project.