Over the last decade, the industry is moving away from the traditional manufacturing process like casting, forging, etc, and adopting sheet metal. The reason being, sheet metal reduces cost and offers high design flexibility. The rolling process is a very common process used in the fabrication industry for sheet metal.

Let us learn more about this rolling process, definition, working principle, application, and rolling process defects.

Rolling Process Definition

The rolling process is a metalworking operation in which metal strips pass through a set of rollers to reduce sheet thickness and achieve uniform thickness throughout the sheet. The sheet is deformed along the linear axis.

Typically after the rolling, metal sheets go through annealing which is done under a closed environment of nitrogen. This is done to make sheet metal corrosion-resistant. After annealing, different chemicals and oil are applied to make sheet metal more corrosion resistant.

Materials used in the rolling process

Below are the list of typical ferrous and non-ferrous materials that are good for rolling process.

Ferrous Material

- Steel

- Stainless Steel

- Galvanized Steel

Non- Ferrous Material

- Aluminium

- Brass

- Copper

- Lead

Types Of Rolling Process

There are two basic types of rolling process based on how rolling is done.

- Hot Rolling

- Cold Rolling

Hot Rolling Process

When the rolling of sheet metal is done above its recrystallization temperature, then it is called hot rolling. Hot rolling may change chemical compositions. The surface finish and dimensional accuracy are not good in the hot rolling process. The typical temperature of hot rolling is about 1700° F. Example of a hot-rolled sheet uses is on the bus or car floor. acoustic floor, truck frames, pipes

Cold Rolling Process

When the rolling is done below its recrystallization temperature, then it is called cold rolling. Cold rolling offers a very good surface finish and you can get excellent dimensional accuracy. A typical example of the application of a cold rolling sheet is in computer enclosures, home appliances, etc. In fact, almost every industry nowadays uses a cold-rolled sheet when precision is important.

Based on the application or how rolled sheets are further processed, rolling can be further divided into following types.

- Flat Rolling

- Ring Rolling

- Roll bending

- Roll forming

- Controlled rolling

- Forged rolling

Must Read: Difference between CRCA vs HRCA sheet

Working Principle Of Rolling Process

The working principle of the rolling process depends on whether you are doing the rolling at room temperature or at an elevated temperature based on the metal. But in both scenarios, the metal sheet gets thinner and length gets increased without affecting the width.

In the case of hot rolling, heat is applied above the re-crystallization temperature of the metal sheet. Due to this heat, the grain structure changes, metal goes to a plastic state and gets deformed to make the sheet thinner.

In some cases, the chemical composition may also be altered to get some desired properties. How much a metal sheet can be thinned depends on the type of metal and rolling machine capacity. Typically hot rolling needs less force than the cold rolling process.

In the case of cold rolling, the mechanism is completely different. No heat is applied in this case. So to deform the metal, the roller has to put a lot of force so that the metal can go to a plastic state. Once it reaches a plastic state, it can be deformed to get the desired thickness. The properties, the chemical composition remains the same as no heat is applied.

You may like to read: Difference between blanking piercing in sheet metal

Types Of Rolling Mills

Below are the few popular types of rolling mills. However many industries use customized rolling mills based on the application requirement.

- Two High Rolling Mills

- Three high rolling mills

- Four high rolling mills

- Tandem rolling mills

- Cluster rolling mills.

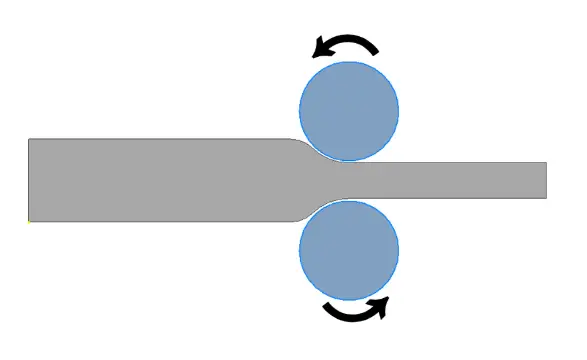

Two high rolling mills

In two high rolling mills, two rollers rotate in the opposite direction and the metal sheet is fed through it. Due to the push force from both rollers, the metal sheet deforms and makes thinner.

There is some variant of two high rolling mills like Non-reversible two high rolling mills in which both the rollers roll in the same direction instead of the opposite direction. There is one more variation in which both rollers roll in both directions. Which type of roller we should use purely depends on how thin you want your sheet metal to be.

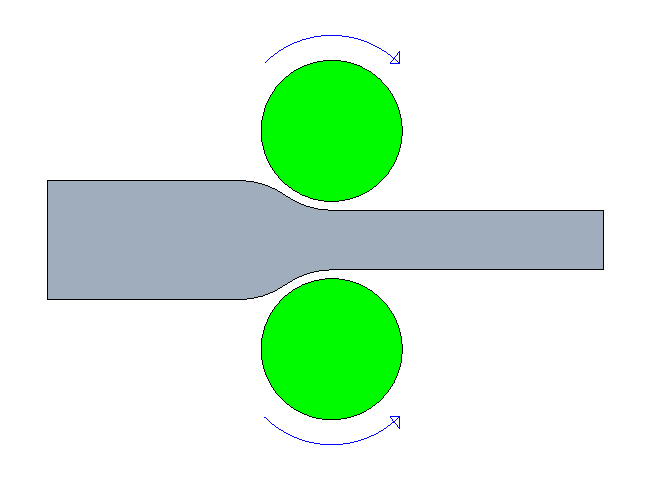

Three high rolling mills

In three high rolling mills, three rollers are placed in parallel. The top and middle roller rolls in the opposite direction, the Same way the middle and bottom roller rolls in the opposite direction.

The metal sheet is placed in between the middle and bottom roller and then it is fed in between the top and middle roller. The benefit of using three rollers is that you can get extremely reduced thickness in the same cycle without affecting the cycle time.

If your main concern is the cycle time then this machine is better than two high rolling mills as you don’t need to take out the sheet from the machine to further reduce the thickness of a sheet which is already thinned while it passed through the bottom and middle roller.

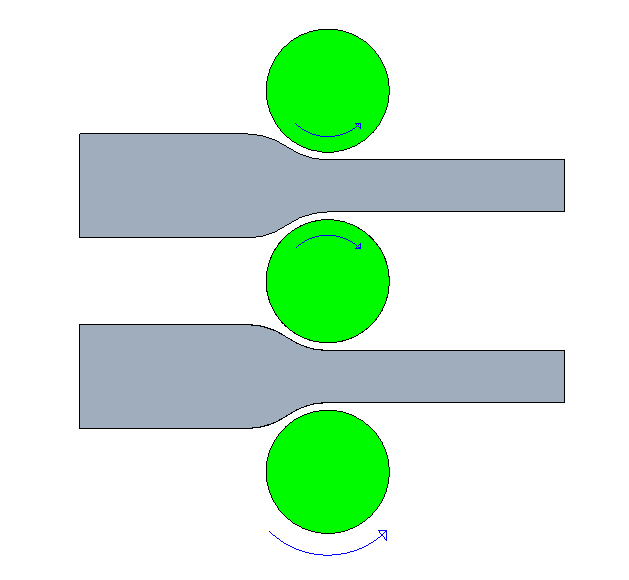

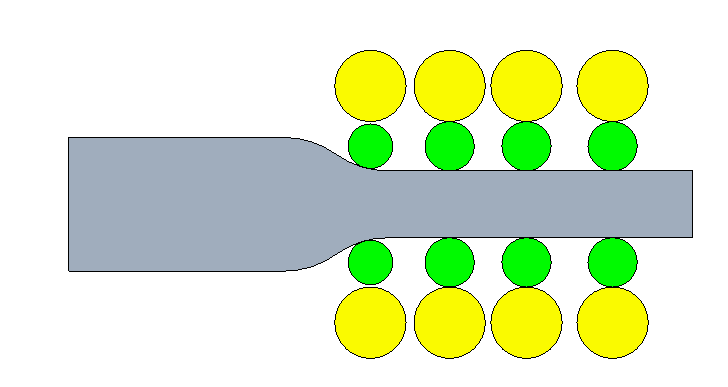

Four high rolling mills

In four high rolling mills, there are four rollers rolls in the opposite direction. Two rollers, each are placed on both sides of the metal sheet. Unlike three high roller mills, the metal sheet will pass through only once.

If you want to further reduce the sheet thickness, you need to take out the sheet from the machine and feed it again. In this rolling machine, the top and bottom rollers are the main rollers, whereas the middle rollers are just backup rollers ( Green Color in the picture).

Tandem rolling mills

Tandem rolling mills use more than two sets of rollers on each side of the metal sheet. For example, using 10 different size roller on one side and the same size roller sets on the opposite side. This is essential when you want to apply heavy force and you won’t load distribution to be linear.

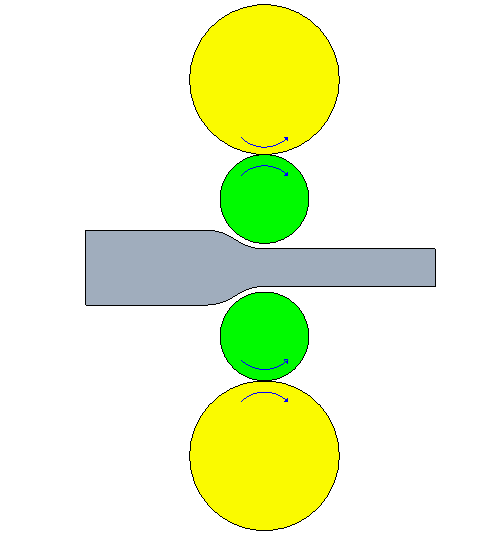

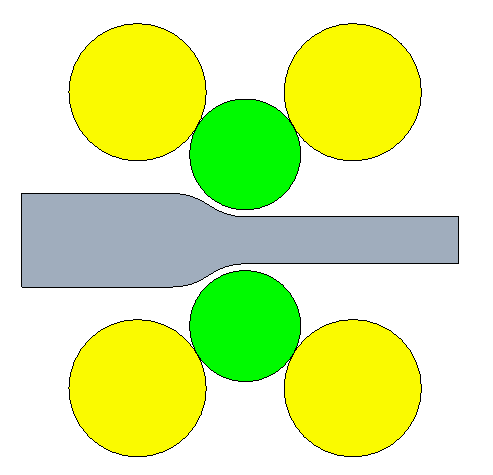

Cluster Rolling mills

Cluster rolling mils uses two basic rollers ( Green color in the image) like two high rolling mills. But it uses 2-3 different size backup rollers on each size. These backup rollers put more pressure on the primary rollers so that metal can be deformed.

Application Of Rolling

There are numerous applications where hot rolled and cold rolled sheets are used. Here are few of those.

Hot Rolled sheet application

- Truck frames

- Bus floor

- Pipe

- Steel bar

- Rail tracks

- Doors

- Guard rails

Cold Rolled sheet application

- Engine canopy

- Enclosures

- Computer cabinets

- Refrigerator doors and case

- Automotive brackets

- Door latch

- Automotive body and door shell

Defects of rolling process

Below are a few key defects found in the rolling process. Often these are due to improper setting of the machine or due to unskilled operators. Sometimes poor sheet quality also plays a role in rolling process defects.

- Wavy Edge

- Edge crack

- Zipper crack

- Alligator crack

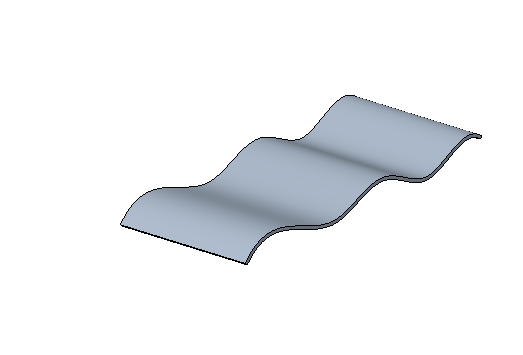

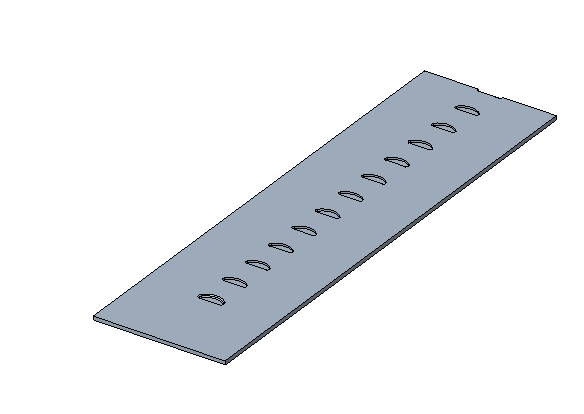

Wavy Edge

This defect occurs due to the improper load distribution on the surface of the sheet. When one area of the sheet is in compression, other areas will be under tension at that point in time.

So there will be always a difference in pressure throughout the sheet. Due to that, you will notice some bulging effect on the edges as a sheet as edges get the least amount of pressure to deform. This type of defect is called wavy edge.

Edge Crack

This is a very common defect in hot rolling. When the hot metal sheet starts getting cooled it is placed under any quenching medium. Due to the difference in temperature, the metal sheet starts to shrink which results in a crack at the edges. This is similar to what we see in plastic injection molding

Zipper Crack

Due to the uneven stress along the centerline of the metal sheet, some small crack occurs, which looks like a zip. These cracks are called Zipper cracks.

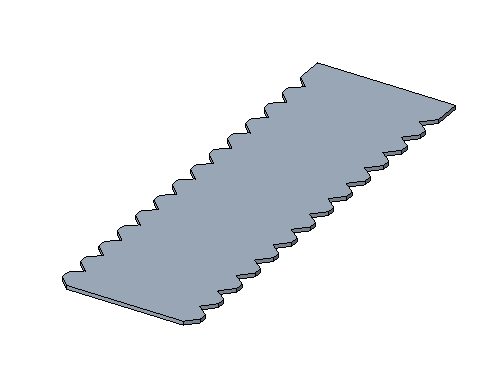

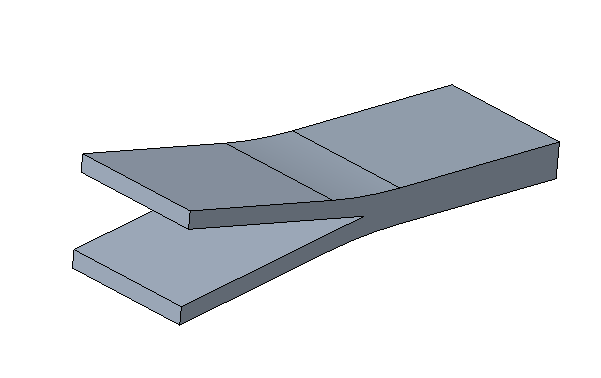

Alligator Crack

Alligator cracks occur due to the non-homogeneous flow of material along with the thickness of the sheet. Usually, metal sheets are made of different layers of metals. During rolling, many layers may detach from the others which resulted in the shape of an alligator mouth. That is why it is called alligator crack.

Conclusion

As I said at the very beginning of this article that, the industry is moving towards sheet metal due to reduced cost and design flexibility. So a mechanical engineer, it is essential to learn about this basic rolling process so that you can make some wise decisions if you are working in the fabrication industry.

The rolling process is also one of the widely used and cheap manufacturing methods to change the thickness of any metal sheet without compromising the structural ability and machinability. I hope this article could able to offer enough knowledge to heads up on this topic. Rest is assured that if you encounter any doubts, I am here to get you on track.

Frequently Asked Questions ( FAQ)

What Is Rolling Process?

Rolling is a metalworking process to reduce the thickness of the metal sheet with the help of rollers. The metal sheet is passed through rotating rollers which puts pressure on the sheet. When that pressure becomes too excessive, the metal sheets go into a plastic state and deformation occurs.

What are the types of rolling?

There are two types of rolling. Hot Rolling and Cold Rolling

What are the types of rolling mills?

Two High rolling mills

Three high rolling mills

Four high rolling mills

Tandem Rolling mills

Cluster rolling mills

What is the temperature of hot rolling process?

1600-1700 ° F