Do you know why many of the design fails? It is all because we don’t care about how a part may fit into other parts. Whatever machines you are seeing around the world are comprised of different parts fitted together. So it’s essential to know about fits to become a better product designer. Let’s learn in this article more about types of fit with different examples.

What is Engineering Fit?

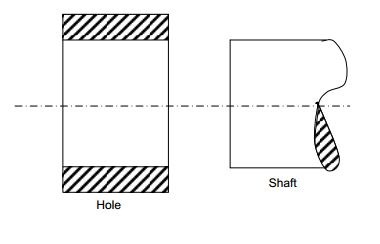

In mechanical engineering, Fit means the clearance/ interference between two mating parts. It is the amount of interaction that exists when two parts are assembled together.

The fit between the two parts defines if the part will be permanently locked or can be freely moved or will resist translation. Design of fit should be done at the beginning of the product design cycle to avoid any issues thereafter. Improper design of fit can lead to product failure.

Both ISO and ANSI have an almost similar set of fit classifications. Usually, fits are described as a hole and shaft pairing system, but ideally fits are not limited to only round objects. Fits can be applied to any part mating with each other. Let’s learn more about the types of fit in this article.

Types of fit

Engineering fits are broadly classified into the following three categories

- Clearance fit

- Interference fit

- Transition fit

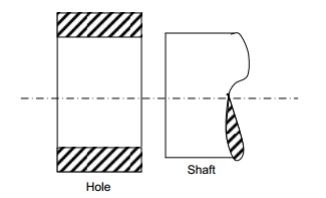

Clearance Fit

Clearance fit ensures that there is always a clearance between two mating parts. If we take the example of a hole and shaft, then the hole size will be always large in case of clearance fit.

Clearance fit examples

- Door Hinge

- Bearing in fans

- A cover of a pen

- Electric switch

Clearance fit types

There are three different types of clearance fit generally used.

- Loose clearance fit

- Running clearance fit

- Sliding clearance fit

Loose clearance fit

In a loose clearance fit, a good amount of clearance is available and precision is not a concern. For example, agricultural Machinery usually has a loose clearance fit

Running clearance fit

Running clearance fit offers the optimum amount of clearance which can be easily filled by lubricant for easy movement of parts. For example, bearing parts.

Sliding clearance fit

The sliding clearance fit has the least amount of clearance for sliding. Usually sliding clearance fit parts are very precise. For example, sliders, Aircraft parts

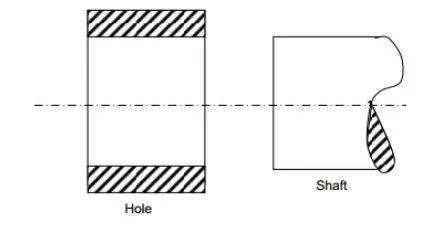

Interference Fit

In case of an interference fit, there will be always interference between two mating parts. If we take the example of a hole and shaft pairing, then the hole size will be always smaller in case of interference fit.

Example of interference fit

- Axel and bearing assembly

- Gaskets in car doors

Interference fit types

Interference fit can be further classified into the following two types

- Forced interference fit

- Shrink interference fit

Forced interference fit

In a forced interference fit, two parts are forced to integrate. A good amount of force is required to assemble both parts together.

Shrink interference fit

In case of a shrink interference fit, parts are heated to alter the mechanical properties, and then both parts are bonded together.

Transition fit

Transition fit can either have clearance if interference. So it is a kind of compromise between the interference fit and clearance fit. Transition fits are important when the location of the shaft and hole is important rather than the fit of both parts. That is way always there will be either interference or a clearance.

Transition fit types

Transition fit is further classified into three types.

- Push transition fit

- Force transition fit

- Wringing transition fit

Push transition fit

In push transition fit, a light push is required to assemble the hole and shaft.

Force transition fit

A considerable amount of force is required for a force transition fit. Sometimes heat is applied to ease in fitting

Wringing transition fit

Wringing transition is applied when there is a negative allowance between two mating parts. A good amount of force is required for wringing transition fit.

System of fit

The system of fits is the required standard based on which counterparts are manufactured. For example, let’s consider the example of our electric socket, the hole diameter in the socket is constant and its standard hole size. Based on this hole size various manufacturers will produce mobile/ laptop chargers. Right? So, in this case, it’s a hole-based system of fit. There are basically two types of systems of fits.

- Hole based system

- Shaft based system

Hole based system

In the hole based system, the hole is set up as a basic dimension and the shaft dimension are varied to get the required fit. I already gave the example of an electrical socket which is a hole-based system.

Shaft based system

In shaft based system, the shaft size is set up as a basic dimension and the hole size varies based on the type of requirement. Consider the example of a screw. The screw size is basic. The hole size varies based on the screw.

Conclusion: Types Of fit

A thorough understating of engineering fits is essential if you want to do good product design. The improper fit design may lead to poor products and ultimately more failure and rejection. This also leads to an increase in product design costs due to rework and manufacturing issues.

That’s all I have in this article. Hopefully, this article may help you a bit to understand the concept of engineering fits and different types of fits. If you have any questions or feel like I missed anything here, please do write in the comment section and I will be happy to answer.