Gauges play an important role in metrology. Let’s learn about different types of gauges used in Metrology and what are the advantages and disadvantages of using Gauges.

What is a Gauge?

A gauge is a device that measures a product’s dimensions about the maximum and minimum permitted values. Without knowing the exact dimension value, mass production commonly uses it to separate acceptable from unacceptable products.

Gauges are non-scaled design inspection equipment used by the company to verify the measurements of manufactured goods.

Gauges do not accurately measure the dimensions of the work being inspected. You can use these tools to check if a product has been manufactured to the required standards.

Purpose of Gauges

- Components must be manufactured within the specified tolerances, which include an upper and lower limit for each. The dimensions of each component must fall within this upper and lower range.

- Using any measuring device to verify these dimensions will take longer. Still, we don’t care how much error there is in the object’s dimensions.

- Parts that don’t fit within these parameters will be discarded.

- The dimensions of a component must meet the requirements, regardless of its size. These gauges, also referred to as limit gauges, can assist us in achieving this objective.

Types of Gauges in Metrology

Metrologists use many types of gauges in their day-to-day work. Linear and angular dimensions may be measured by using gauges.

Metrologists use gauges to get precise readings of physical quantities in the lab or on the job site. The following are the different types of gauges used in metrology.

Plug Gauge

A cylindrical, dumble-like gauge is known as a plug gauge. There is a go gauge on one side and a no-go gauge on the other.

Gauges are inspection tools that confirm the dimensions of manufactured items but do not include a scale. It is employed to determine the size of an interior hole. It’s an attribute-typed gauge.

Since there is no other way to determine whether a portion is good or bad, it is known as an attribute gauge. It has no variable values of any kind.

The maximum material condition of the product is indicated by a “GO” gauge, while a “NO GO” gauge indicates the minimum material condition.

Snap Gauge

To determine a part or material’s diameter or thickness, the snap gauge, also referred to as a gap gauge, is a metrology tool.

These tools are adaptable and made to quickly determine whether to proceed with machining operations on cylinders, shafts, grooves, and other similar parts and features.

Functionally, snap gauges evaluate the outside diameters of parts in a manner akin to that of other tools and measuring devices like ring gauges and thickness gauges.

While ring gauges are only for cylindrical parts, snap gauges can be used to check the dimensions of both cylindrical and non-cylindrical parts.

A snap gauge is an inspection and quality control tool that assesses whether the part’s outside dimensions fall within the tolerances set.

It is primarily a gauging tool and, as such, is made to evaluate whether the part complies with its dimensional requirements without directly providing a measurement of that dimension’s actual value.

Ring Gauge

A ring gauge measures the diameter of an object’s outer circumference. The ring gauge, as its name suggests, looks like a ring. Using a ring gauge, you can tell if a ring is in the “go” or “no-go” range.

No-Go Gauge is used to determine whether a part is acceptable or not based on the tolerances specified. Non-Conforming parts pass the Go-Ring gauge but fail the No-Go gauge.

It is possible to use ring gauges to measure the outer diameter of various cylindrical parts, including pins, shafting, fasteners, and other machined cylindrical parts.

The outer diameter of machined parts is checked with ring gauges, which serve as a stand-in for micrometer gauges and other instruments. Using a ring gauge rather than a micrometer saves time when it comes to verifying parts.

Feeler Gauge

When determining the distance between two components, feeler gauges are frequently used as a measuring tool.

These gauges work well to measure clearance, determine small spacing, measure narrow slots, and assess the fit of mating parts. It is also known as a thickness gauge.

The filler gauge is frequently used to modify the spark gap between a car’s distributor points. These gauges are composed of several thin strips or sheet blades with a marked thickness on each strip.

The entire set comprises several strips that have been assembled and range in thickness. Each strip is typically prepared up to 12.5 mm wide. The blade must slide smoothly between the mating parts during use rather than being forced between them.

Radius or Fillet Gauge

The curvature radii of convex and concave surfaces and shoulders can be verified using these gauges, which cover a range of 1–25 mm. As depicted in the diagram, the gauges are made up of thin plates with varying radii at the ends.

16 concave and 16 convex blades make up each set of 16. Component inspection and tool layout are two common uses of a radius gauge in the manufacturing industry.

Screw Pitch Gauge

A screw pitch gauge is essential for determining the pitch of a screw’s threads and selecting the correct one. As shown in the figure, they are made up of a holder and some flat blades cut out to a specific pitch.

To identify which thread they are intended for, blades and holders have a pitch or number of threads per inch stamp. For metric threads, the sets come with a 60-degree angle; for English threads, the angle is 55 degrees.

Dial Gauge

The dial gauge is a type of indication gauge that is available in several least counts. There are two types of dial gauges: plunger dial gauges and puppy dial gauges.

A dial gauge is a device used to measure deviations from expected norms, and dial gauges evaluate surface profiles, pressure, and other variables.

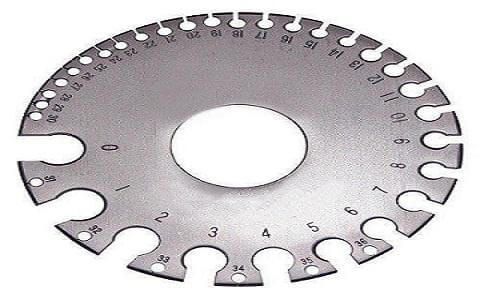

Plate Gauge and Wire Gauge

Wire gauges measure wire diameters, while plate gauges measure sheet metal thickness. The plate and wire gauges in the picture are used to measure the thickness of metal from 0.24 to 5.0 mm, respectively.

Height Gauge

Height gauges are precision measuring instruments that can also provide notable locations on an object relative to a reference plane for subsequent use to determine the height of an object or workpiece with extreme precision and accuracy.

Caliper Gauge

The Caliper Gauge is the gauge used to measure an object’s distance between two sides. It is very useful as it can give more accurate results and is very easy to use. Such examples are vernier caliper, dial caliper, digital Caliper, micrometer caliper, etc.

Advantages of Gauges

- It is now possible to quickly determine if a product is within the specified tolerances. Consequently, the outcome is not influenced by operator judgment, as there is less reliance on operator competence in this case.

- It is possible to check more than one product dimension at a time along with properties such as roundness, taper, etc.

- These devices are self-contained in terms of power.

- There are a variety of methods for examining dimensions.

- They are easy to set up and don’t require any additional equipment.

- Comparatively, they’re less expensive than standard measurement devices.

Disadvantages of Gauges

- Gauges lose accuracy over time due to normal use and abuse.

- Despite being within the work tolerances, some components may be rejected by the workshop gauges. Since they must be re-inspected with inspection gauges before being accepted, this is a requirement.

- Workshop and inspection gauges must be built separately due to differences in tolerance zones.

- Inspection gauges can be used to determine whether or not a component falls outside of the acceptable working tolerances.

- A product’s dimension has an unknown numerical value.

Conclusion: Types Of Gauges

A gauge is an inspection tool used by engineers to determine a component’s tolerance limit. Engineers primarily use gauges to determine the appropriate dimension of a workpiece. Manufacturers must work within some fundamental constraints when creating a gauge.

Gauges, as described above, are essential to the field of metrology. In determining a machine’s mechanical advantage and efficiency, the precision of a machine component is a key factor to be considered.