Injection molding is the widely used manufacturing process to manufacture simple to complex plastic parts. But do you know there are different types of an injection mold that you can choose from? Let’s learn in this article about different types of injection molds.

Importance of choosing a correct mold type

Choosing the correct mold type is essential for business. Choosing a mold type may affect the initial investment but it may reduce the cost in the long run. So the overall part design, quantity forecast has to be done before you land on choosing a mold. You may be tempted by some mold types which cost cheap but if that does not suit your product, you may be losing a lot of money

Choosing a particular type of injection mold depends on many factors. The part design and size of a part have a big impact on the types of mold that you can choose. In fact, the part quality and appearance surface requirement also affect the decision of choosing a particular mold type. Here is a list of broad factors that might influence the decision of a specific injection mold type.

• Part overall size or volume

• Part quantity per year

• Part complexity

• Straight pull or lifter /slider required for part removal

• Appearance surface requirement

• High gloss requirement

• Regrind allowed or not

• Types of plastic material used

• Supplier compatibility and availability.

• Cost vs feature ratio

Types of Injection Molds

Now that we know that what factor can influence the decision of certain injection mold type, let find out Types of Injection molds based on the following criteria

• Number of parts

• Mold opening mechanism

• Feeding system requirement

Based on the number of parts, injection molds are further decided into the following categories

- Single Cavity Mold

- Multi Cavity Mold

- Family mold

Based on Mold opening mechanism, injection molds are decided into the following categories.

- Two plate mold

- Three plate mold

- Stacked Mold

Base on the feeding system, injection molds are further decided into below categories

- Hot runner mold

- Cold runner mold

Also Read: Two Plate Mold Vs Three Plate Mold

Single Cavity Mold

Single Cavity Mold can only mold a single part per shot. The mold design is simple and the cost is low. This type of mold is ideal for big size part and if the part quantity is less.

The mold machine tonnage limitation is one of the prime reasons many companies go for single Cavity Mold for big parts. Repair of mold is comparatively easy and you can control the turn around time.

Multi Cavity Mold

As the name suggests, multi-cavity mold can produce multiple parts per shot. It is ideal for Mass volume and smaller parts. The number of cavities that a mold can have depends on part size.

Multi cavity molds are costly to make and repair. Higher tonnage injection molding is required for multi-cavity molds. Usually higher production volume parts are molded in the multi-cavity mold. Although the initial investment is high in the long run, it might be more economical.

Family Molds

Family Molds can produce multiple parts ( Different designs) in a single cycle. Unlike multi-cavity where usually the same part with multiple quantities is produced.

Family mold is ideal for low quantity parts and suitable for prototypes rather than production parts. However, there are exceptions when companies use a family mold for production parts.

Ideally, companies use family molds for parts that have a right and left-hand combination. Please make a note that family molds are only used for parts which have similar materials, color, and finishes.

Two plate mold

As the name suggests two-plate mold uses two plates, one is the core and the other is a cavity. It has only one parting line. The part eject in one operation.

But the problem with two-plate mold is that the runner solidifies along with the part and ejected with the part. So secondary operation is needed to remove runners from the part. However, those runner materials can be regrinded in the hopper if the part design requirement allows it.

Since the second operation is needed to remove runners, the overall process is slow. But since the mold cost is cheaper, companies usually do a trade-off between chapter mold or slow production.

One more issue with the two plate mold is that the gate location does not have much flexibility. In most of the cases gates are provided on the side of the part which is a problem if the part has an appearance surface on the side.

Three Plate mold

Three Plate mold uses an extra striper plate which houses the runner. It has a double-action ejection system and the runner does not eject with the part. The part has two parting lines. Usually, runners are always heated in three plate mold.

Since the runner is detached when the part is ejected so no need for any secondary operation. This reduces overall cycle time and a faster production rate. Three Plate mold is ideal for Mass production but the initial setup cost is high.

Three Plate mold often called a runner less mold or hot runner mold has the flexibility of gate location change anywhere in the part. Since the runner is on a different plate so you can place the gate anywhere in the part.

The cost of making a three-plate mold is high. But it eliminates many extra processes and for mass production, the cost can be absorbed. Don’t forget that the three plate mold offers good appearance surfaces compare to the two plate mold. So if the part quality is a concern then three plate mold is the one you should choose

Stacked Mold

Stacked injection mold uses a grid of cavities. What that means is that you can have multiple cavity setup in a single machine. For example, if you have 4 single Cavities arranged in a stack in an injection machine then in every cycle you will get identical 4 parts rather than just one. This increases machine efficiency.

Stack mold is useful when you don’t have an option to accommodate a higher tonnage injection molding machine but want to have multiple parts in a single shot. The mold cost is too high due to the complex configuration, but it also reduces multiple processes and you get multiple parts in a single operation.

Stacked mold is yet very popular in the industry due to complex mold design and cost. But slowly big manufacturers are trying stacked mold to increase production rate and lower the cycle time.

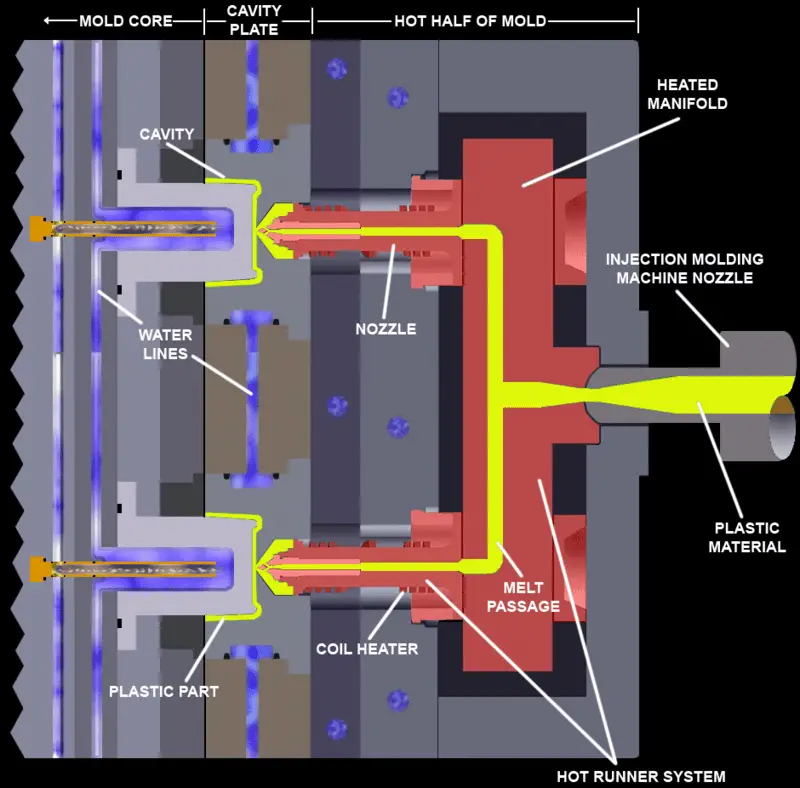

Hot Runner Mold

Hot runner mold uses a preheated runner system usually heated by a rod, coils, or heating elements. The runner system usually houses in a stationary plate which we generally call three-plate mold.

The runner systems keep themselves hot even when the part is getting cold. That’s why runners are not ejected with the part and we call it as runner less mold. This saves any extra process that is required to remove the runner.

Hot runner molds are usually costly as we need to have a heating mechanism to heat up the runner. It also adds a separate plate to the mold which adds up cost.

Since the runner is hidden in the mold so cleaning the runner system is a problem. In case you want to change the material of the part, the mold required an extensive level of service before it can adopt new material.

Cold Runner Mold

Cold Runner mold does not have a heating mechanism for runners and parts are ejected with runners attached. A separate process is required to remove those runners.

These additional process adds time and cost and thus not preferred for Mass production where cycle time is very important.

Cold runner mold also creates a lot of waste because of the trimmed runner. Though those runners can be regrinded that affects parts quality and many businesses do not want that.

However cold runner molds are cheap to build and changing the material of part does not need extensive servicing. It’s really a good option for low volume parts.

3D Printed Mold

This type of mold is the latest addition to injection mold types. This is made of plastic and suitable for 50-100 cycles. Ideal for making prototypes and trial part.

Since this type of mold is made of plastic whose melting point is higher than the part melting point, so after a few cycles, those molds start degrading.

The cost of 3D printed molds are very high but can be made in just 24 hours. Whereas metal mold takes 4-8 weeks and includes multiple parts and complex design.

Conclusion

I hope you got a fair idea about various injection mold types. Though this list is not exclusive and there are many more types of molds available. Also, companies generally use a combination of different types of mold to get the best result.

I am always open to discussion and if you feel that something I have missed here then doesn’t hesitate to comment in the comment section. I will be happy to respond to you.

In case you know about any other mold type then do let me know and I will include those in the list.