In GD & T, often we hear about the term called ” Bonus Tolerance.” Most of the engineering drawings have bonus tolerance mentioned nowadays. Have you ever wondered what bonus tolerance is? Let’s discuss it in this article.

Before you know about bonus tolerance, it is very much essential that you know about the maximum material condition ( MMC) and least material condition ( LMC)

I have written one dedicated article on MMC and LMC . Please read that article first and then come here

Must Read : What is MMC and LMC

What is bonus tolerance?

Bonus Tolerance is the amount of extra tolerance that a feature is privileged to get when the feature of size departs from MMC to LMC

Let me give an example to make you guys understand what is bonus tolerance.

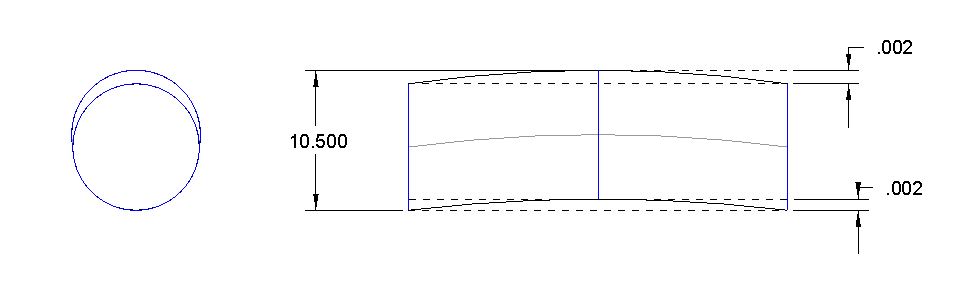

Here is a simple cylinder with a diameter of 10.000 inches, and tolerance is +.500/-.003. So the MMC of the cylinder is 10.500 and LMC is 9.700

You also see a straightness tolerance of .002 at MMC what means that at MMC ( Dia 10.500), the maximum straightness tolerance is .002.

What if the cylinder is not at MMC and shifts towards LMC. For example, let’s say the cylinder size is 10.400 inches. In that case, the straightness tolerance will get (10.500-10.400) .001 inch extra tolerance apart from regular .002 inch tolerance. This .001 inch tolerance is called Bonus Tolerance.

Bonus Tolerance Calculator

Bonus tolerance calculated using the following formula. The table shows the bonus tolerance of the straightness in regards to the figure shown above.

Bonus Tolerance= MMC-Actual Size

| Part Size | Straightness Tolerance | Bonus Tolerance | Total Straightness Tolerance |

|---|---|---|---|

| 10.500 | .002 | 000 | .002 |

| 10.400 | .002 | .001 | .003 |

| 10.300 | .002 | .002 | .004 |

| 10.200 | .002 | .003 | .005 |

| 10.100 | .002 | .004 | .006 |

| 10.000 | .002 | .005 | .007 |

| 9.900 | .002 | .006 | .008 |

| 9.800 | .002 | .007 | .009 |

| 9.700 | .002 | .008 | .100 |

You may like to read: What are two GD & T rules

Why Bonus tolerance is important

We all know that making a part with the basic dimension is next to impossible, and it’s costly too. So manufacturers started tolerancing. But again, too tight tolerance is equal to no tolerance.

That is when bonus tolerance comes into the picture. It’s a reward in the form of bonus tolerance if manufactures can produce the feature within MMC. It is giving flexibility to manufacturers to open up the tolerance zone.

Does bonus tolerance affects part cost?

Yes, it does. Bonus tolerance reduces the part cost. The reason being we are giving more freedom to manufacturers to open up a tolerance.

Without bonus tolerance, manufactures are constrained to get tight tolerance that indeed increases part cost. So it always advisable to use bonus tolerance.

Advantages of Bonus Tolerance

- Open up tolerance zone

- Offers flexibility to manufacturers to get more tolerances.

- Bonus Tolerance increases the part acceptance ratio.

- Assures part interchangeability

- Reduce part cost

Disadvantages of Bonus Tolerance

- Part dimensional quality is a concern

- A tight fit is not possible

- Precision assembly is a big problem.

Conclusion

Bonus tolerance is the new standard in engineering drawings. Almost every manufacturing drawing has bonus tolerances. It also got adopted very widely because it reduces part cost without hampering the part quality.

I hope I could able to explain what bonus tolerance is. If you still have any concerns, please write to me in the comment section, and I will be happy to respond.

Frequently Asked Question ( FAQ)

What is Bonus Tolerance?

Bonus tolerance is the extra amount of tolerance that a feature gets when the feature of size departs from MMC to LMC

When Bonus Tolerance is available?

When a feature of size departs from MMC to LMC , bonus tolerance is available.

Does bonus Tolerance reduce part cost?

Yes, it does as we are giving more flexibility to manufacturer to increase the tolerance zone

Is there any bonus tolerance symbol

No, There is no symbol

What is the difference between bonus tolerance and virtual condition?

Bonus tolerance is added to geometrical tolerances to achieve virtual condition