A projected tolerance zone is used in threaded holes to specify the projected area that this tolerance will cover. This ensures that the clearance hole in the mating part is also in-spec so that a stud, dowel pin, or screw can be used to fasten the parts.

A projected tolerance zone is widely used in areas where two or more mating parts are assembled using a screw or similar hardware. Let’s learn more about Projected Tolerance Zone in this article.

Projected Tolerance Zone Definition

A projected tolerance zone is the area that the main tolerance can be projected into so that the tolerance covers the base part and the mating part.

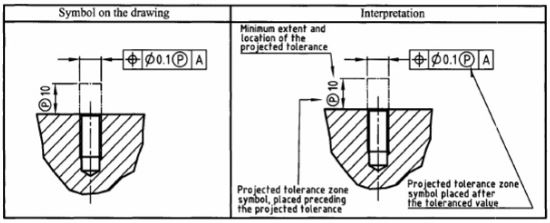

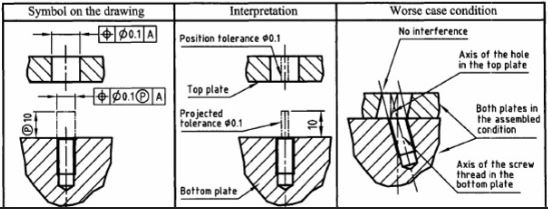

To understand the Projected Tolerance Zone, let us take this below example.

In this picture, you have seen that a symbol P is used with 10 as the value. That is the projected tolerance zone symbol, and 10 is the value up to which the tolerance value will be applied.

So here, 10-inch height is the area beyond the base part. Since this projected tolerance zone is covering the clearance hole position tolerance, so even in the worst case, the pin will fit without interference. The projected tolerance zone value can be achieved by calculating how much distance the pin will travel inside the clearance hole.

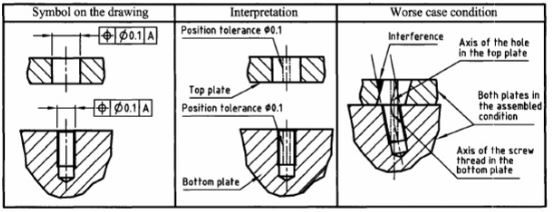

Now in the below picture, we have given position tolerance only to the base part. As a result, there is a chance that the pin may interfere with the mating part when assembled.

Projected Tolerance Zone Symbol

The project tolerance zone is specified by a circled P, also known as a P modifier in GD&T vocabulary. The projected tolerance zone is specified next to the position tolerance and only applicable to circular objects.

Is there any alternate to using a projected tolerance zone?

The projected tolerance zone is indeed a complicated concept. You need to know about the mating part before you decide on the projected tolerance. Many engineers prefer not to use projected tolerance, and instead, they open up the base tolerance.

That is fairly good, but the problem is that when you open up the base tolerance, the quality gets decreased, and if that part is used in areas where leaking is a concern, then the whole concept will fail.

That is why it is always advisable to use projected tolerance zone instead of opening up the base tolerance.

Projected Tolerance Zone application

The projected tolerance zone is only applied to threaded holes or simple holes where two mating parts will be assembled using a pin, screw, nut, or similar hardware.

Projected Tolerance Zone Advantages

- The tolerance is projected to the mating part

- Less part rejection

- Better part accuracy

- Part can be manufactured using tight tolerance

- Minimum clearance between mating parts

Projected Tolerance Zone Disadvantages

- The base part tolerance depends on the mating part

- Need to control the tolerance of the mating part to meet the projected tolerance zone

- Higher part cost

- Experience engineers are required for complex tolerance stack-up analysis.

Conclusion: projected Tolerance Zone

The projected tolerance zone is a complicated concept and needs the experience to become a master in it. However, I believe that this article gave you a basic idea about the projected tolerance zone. When you work on real projects, you may be able to understand this concept better.

If you still have some questions or queries, please don’t hesitate to ask that in the comment section, and I will be happy to answer.

You can explore the GD&T section for many useful articles on advanced GD&T and its applications

You may also like to read: