You all might have noticed that sometimes it’s very difficult to insert a circular object into its counterparts. Right? This is all because the circular part was not made with Circularity tolerance in consideration.

Circularity tolerance plays a big role in getting precise cylindrical parts. So in this article, we will discuss Circularity tolerance in GD&T and how it affects part quality.

What is Circularity Tolerance: Circularity Definition

Circularity Tolerance specifies how close every cross-section of a cylinder should be from a true circle. It is not possible to make every cross-section of a cylinder perfectly circle. That is why we need to allow some tolerance, and that tolerance is called Circularity tolerance.

Circularity tolerance is a form tolerance. What that means is that circularity tolerance does not refer to or depend on any datum. Also, no material modifier like MMC or LMC is applicable.

When diameter tolerance is specified on top of circularity tolerance, then the circularity tolerance is always less than the diameter tolerance. Circularity tolerance is a 2D tolerance that controls the circularity of every cross-section of a cylinder, whereas cylindricity is a 3D tolerance that applies to the whole surface of the cylinder.

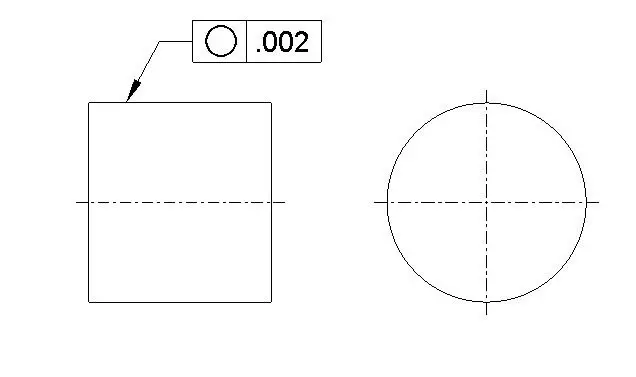

Circularity Tolerance Symbol

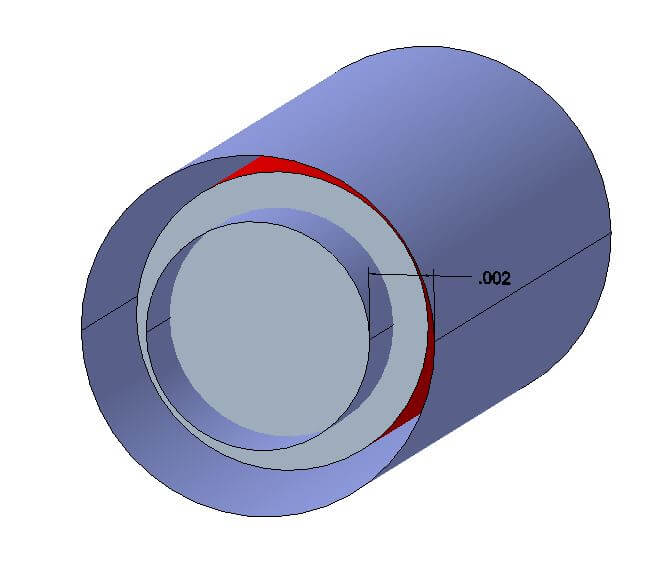

Circularity Tolerance Zone

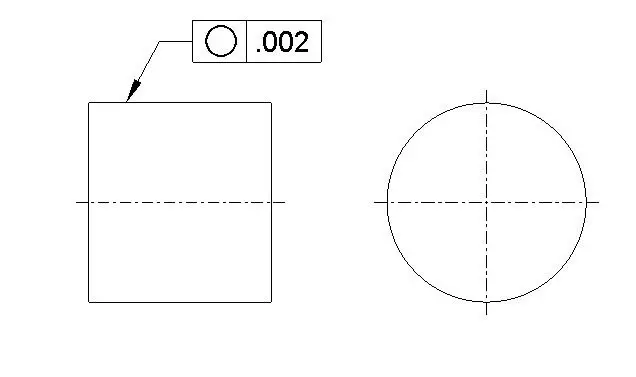

The circularity tolerance zone is specified by two equidistance cylindrical surfaces between which every entity of every cross-section of the cylinder should lie. Here in the below picture, you can see that the red surface should lie between two surfaces that are .002 inches apart.

Circularity Tolerance Drawing Call out

As I said before that circularity tolerance is a form tolerance, so no reference to any datum or material modifier. Here is how it is typically shown on drawings.

How To Measure Circularity Tolerance?

Typically circularity tolerance is measured by a height gauge. The cylinder is rotated after constraining it in all directions, and then the height gauge measures the variations. The total variation in height should be less than the allowance tolerance to qualify the part for production.

When Circularity Tolerance Is Used?

Circularity tolerance is very common in manufacturing. It is often used in cylindrical parts like cylinders, bearing, pipes, pins, holes, etc. If the cylindrical tolerance is tight, it creates interference or transition fit, and if the tolerance is too high, it creates a clearance fit. You can learn about types of fit by clicking here.

Conclusion: Circularity Tolerance in GD&T

That’s all I have in this article. I hope I could give you enough insights about circularity tolerance, the Circularity tolerance symbol, and how to use the circularity symbol. Circularity tolerance is a fundamental form of form tolerance and is often used in industries to make precision cylindrical parts.

If you have some questions or want to know more about circularity tolerance, please don’t hesitate to write in the comment section and I will be happy to help you out.

Frequently Asked Questions (FAQ)

What Is Circularity Tolerance?

Circularity tolerance is a form tolerance that offers the amount of deviation that a circle in every cross-section can have from the true circle size. of a cylindrical part.

How To measure Circularity Tolerance?

Circularity tolerance can be measured using a height gauge. You need to constrain the object first and then rotate it. The height gauge should touch the surface of the part. While rotating, any deviation can be captured and compared with the specified tolerance.

Does circularity tolerance need a datum reference?

No, Since it is a form tolerance

Circularity tolerance can have MMC or LMC modifier?

No, It is not required.