Cyclindricity tolerance plays a big in the proper assembling of cylindrical parts. If cylindricity tolerance is not considered, then there are chances that parts may not get assembled properly. Let’s discuss Cylindricity Tolerance in this article and explore how it can affect part quality.

What Is Cylindricity Tolerance: Cyclindricity Definition

Cylindricity tolerance is a form tolerance that describes the amount of deviation a cylindrical surface can have from a true cylinder. It is a 3D version of circularity tolerance. In the case of circular tolerance, circles of every cross-section are considered but with cylindricity, the whole surface is considered.

Cyclindricity is a combination of circular tolerance and straightness tolerance. If a surface meets the cylindricity tolerance, it will also meet the circularity tolerance, and the axis of the cylinder will meet the straightness tolerance.

When cylindricity is used on top of diameter tolerance, then the cylindricity tolerance is always less than the diameter tolerance.

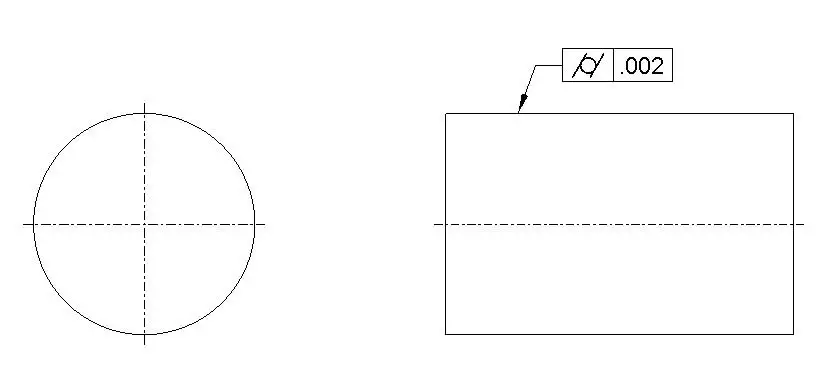

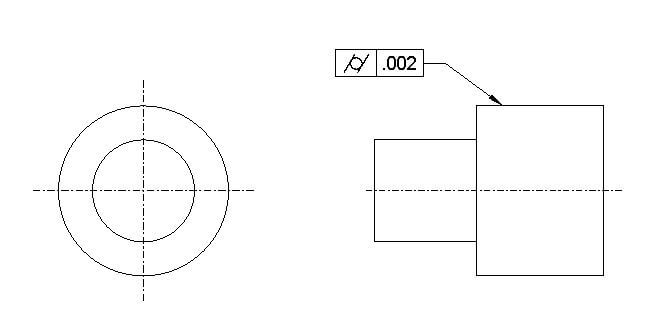

Cylindricity Tolerance Symbol

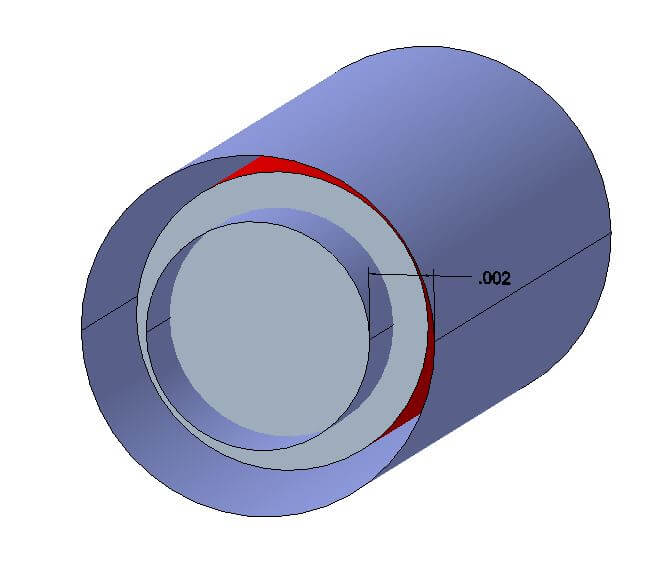

Cylindricity Tolerance Zone

Two equally distanced surfaces create the cylindrical tolerance zone as per the cylindrical tolerance value. The specified surface ( Red surface in the below case) should not deviate beyond these two surfaces.

Cylindricity Tolerance Drawing Callout

The below image shows how circularity tolerance is shown in the drawing. Since it’s a form of tolerance, so no modifier or datum reference is required.

How To Measure Cylindricity

Cylindricity can be measured using a height gauge. You need to constrain the cylinder along the axis and then rotate it. A height gauge then touches the outer surface of the cylinder. Due to cylindricity tolerance, there will be some variation in the height gauge movement. Make a note of that amount of height gauge movement, and that will be your cylindricity tolerance value. If the value is less than the value specified in the drawing, then the part is qualified.

When Cylindricity Tolerance Is Used?

Cylindricity tolerance is very common in the industry. It is often used in critical cylindrical parts where precision is most important for assembling parts like a bush, pin, pipe, cylinders, etc. Without proper cylindrical tolerance, there is a high chance that the part may not fit, or there may be leaks if the part is way out of tolerance.

Conclusion: Cylindricity Tolerance In GD&T

That’s all we have in this article about cylindrical tolerance. This is just a brief introduction to what cylindrical tolerance is and how that is shown in the drawing. This a fundamental type of form tolerance to control the shape of individual objects without relating to any feature of size or position of features.

If you have any questions or queries, you are always welcome to write in the comment section, and then I will be happy to assist you.

Frequently Asked Questions (FAQ): Cylindrical Tolerance

What Is Cylindrical Tolerance In GD&T

Cylindrical tolerance in GD&T is the amount of deviation a cylinder can have from the true cylinder size. Cylindrical tolerance is a combination of circularity tolerance and straightness tolerance.

How To Measure Cylindricity?

Cylindricity tolerance can be measured using a height gauge. You need to constrain the part and rotate it along its axis. And then measure the amount of deviation in the height gauge movement.

Do we need datum reference in Cylindricity Tolerance?

No, Datum reference is not required.

Can we use MMC or LMC modifier in Cylindricity Tolerance?

We can not use MMC or LMC as Cylindricity tolerance is a form tolerance and does not depend on the feature of size.