One of the main questions that come to everyone’s mind is why should we migrate to GD&T? Are there any benefits, or is it to make designers’ lives like hell.

But do you know that industries do not spend millions of dollars without any benefits? And when we talk about benefits, Yes, GD&T gives a lot of benefits in the form of wider tolerance and less part cost.

When we talk about wider tolerance, the tolerance zone comes into the picture. So in this article, we will talk about the tolerance zone and what is the difference between a rectangular tolerance zone and a circular tolerance zone.

What is a tolerance zone?

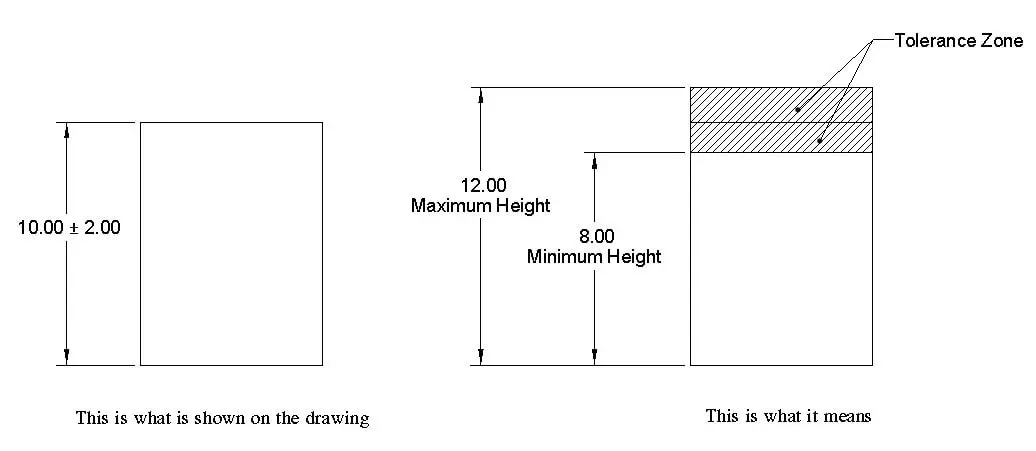

Before we learn about how a tolerance zone gives benefits to manufacturers, we need to understand what basically tolerance zone is. The tolerance zone is the area where the specified entity can lie even after the extreme deviation.

For example, a part has a height dimension of 10+/-2 inches so that the height can go up to 10+2=12 or 10-2=8 inches. So the zone created by the dimensions 8 inches and 12 inches is called a tolerance zone. The top surfaces can lie anywhere in this tolerance zone, and the part will be accepted.

Types Of Tolerance zone

There are two types of tolerance zone available.

- Rectangular Tolerance Zone

- Circular Tolerance Zone

Rectangular tolerance zone

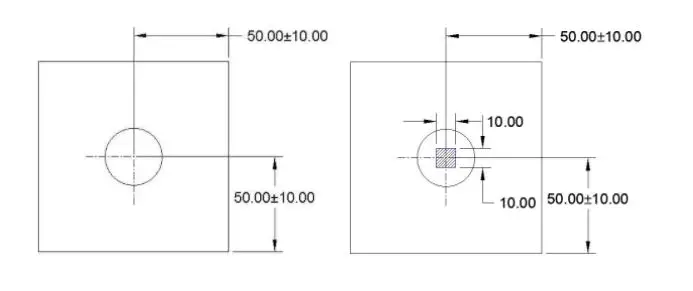

The rectangular tolerance zone is only available in the traditional liner dimensioning and tolerancing method. If you see the below example, the hole axis position is controlled by two-liner tolerance of 10.00 inches in the X and Y direction.

If you draw the tolerance zone, then it will be like a square box having dimensions 10X10 as shown in the below image.

Circular Tolerance Zone

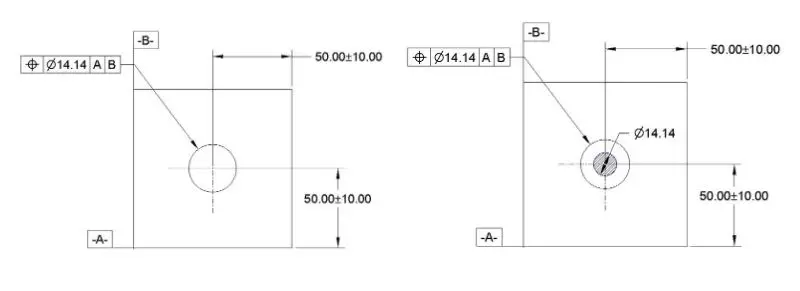

A circular tolerance zone is available when you apply GD&T on any features. For example, if we take the same example as shown above and apply geometric tolerances, you will notice that it creates a circular tolerance zone having a diameter of 14.14 inches.

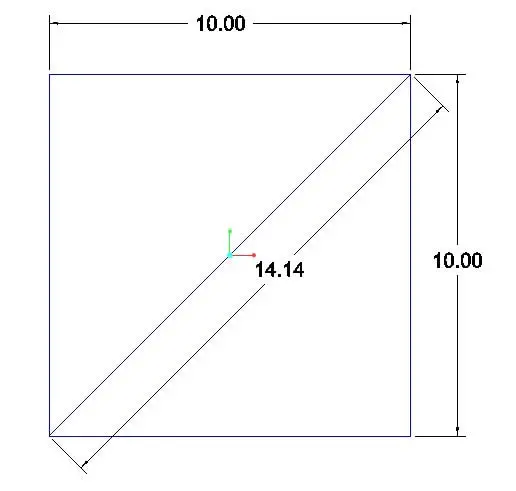

Now you might be wondering how I derive the value 14.14. For a moment, you may feel that I have taken a larger dimension for the circular tolerance zone. But that is not the fact. If you take the rectangular tolerance zone and measure the diagonals, it will be 14.14 inches only.

So basically, for both rectangular and circular tolerance zone, we have taken the same tolerance value. The only difference is that in the rectangular tolerance zone, we have taken the length and height value, and in the case of the circular tolerance zone, we have taken the diagonal value.

Rectangular Tolerance Zone Vs Circular Tolerance Zone

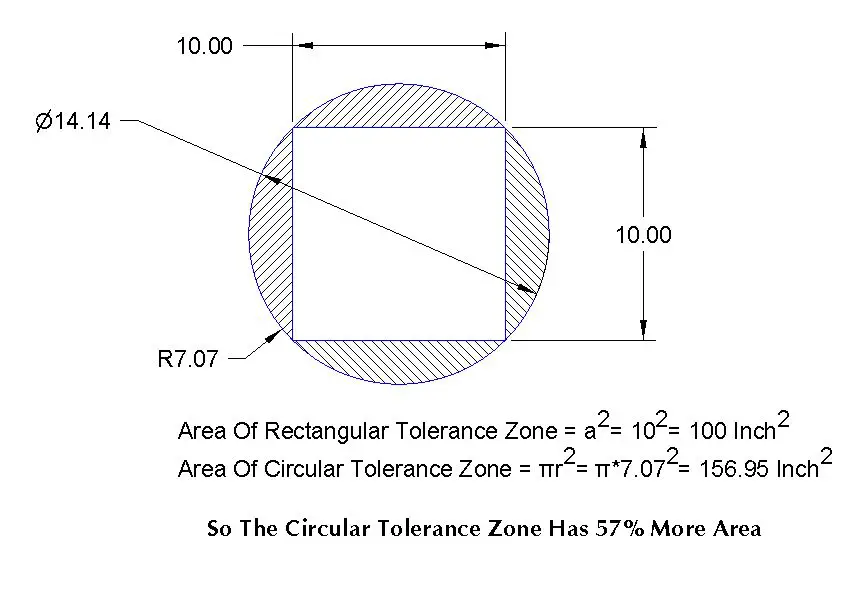

In the below image we have shown the differences between the rectangular tolerance zone and the circular tolerance zone.

Here you see that the Area of the rectangular tolerance zone is 100 Square Inches whereas the Area of the circular tolerance zone is 156.95 Square Inches. So even with the same tolerance in both linear tolerancing and geometric tolerancing, we are getting more area in the circular tolerance zone.

So there is about 57% more tolerance zone area ( Hashed area) in the circular tolerance zone.

More tolerance zone area= More flexibility to the manufacturer= Lower part cost= Lower product cost= More Profit

So now you have realized why industries adopt GD & T. Because GD&T can save them a lot of money and product quality also gets improved.

| Rectangular Tolerance Zone | Circular Tolerance Zone |

|---|---|

| Less tolerance zone area | More tolerance zone area |

| Datum reference is optional | Datum reference is a must |

| The design intent is not clear | The design intent is very clear |

| More chances of error during the inspection | Fewer chances of error during the inspection |

| More part rejection | Less part rejection |

| Poor part quality | Better part quality |

| Higher part cost | Lower part cost |

Conclusion: Tolerance Zone

GD&T is a blessing for the industry. There is hardly any company that does not use GD&T nowadays. Having a more tolerance zone area is the key to GD&T success along with other benefits. I hope I could explain to you the tolerance zone and why it is so essential to know if you want to adopt GD&T.

I can understand that GD&T is as simple as we may think. So if you have any questions, please don’t hesitate to write in the comment section, and I will be happy to assist.

You may also like to read:

1. What is the feature control frame in GD&T

Frequently Asked Questions on Tolerance zone

what is the tolerance zone in gD&T?

The tolerance zone in GD&T is the area where all elements of the specified entities should lie. In other words, no elements of the specified entities should fall beyond the area formed by the size tolerance.

How much more tolerance zone area we will get in the circular tolerance zone?

We will get about 57% more area in the circular tolerance zone compared to the rectangular tolerance zone

Does the circular tolerance zone in GD&T adds more cost to the part?

No, not at all. Instead, the part cost goes down as the circular tolerance zone gives wider tolerance to the manufacturer, and there are fewer chances of part rejection.