No surface can be made perfectly flat. Right? It’s next to impossible to make a perfectly flat surface. We have to have some tolerance for how flat a surface should be. That tolerance is called flatness tolerance. Let’s learn more about flatness tolerance in this article.

What Is Flatness Tolerance?

When a surface is perfectly flat ( Theoretical), all surface points should rest on the same plane. In practice, this is not possible. That is why most of the engineering drawings specify flatness tolerance. That means how much deviation is allowed for the surface to deviate with respect to its perfectly flat form.

Since perfect flatness is not possible, flatness tolerance is specified on drawings so that the part can be flat enough to function properly. If any part is way out of the specified flatness tolerance, it may not be accepted in production as it may not fulfill the purpose.

When flatness tolerance is specified on top of any dimensional tolerance, then the flatness tolerance is always less than the dimensional tolerance.

Flatness is the 3D version of straightness tolerance and needs to be measured all across the specified surface.

Must Read: GD&T symbols with examples

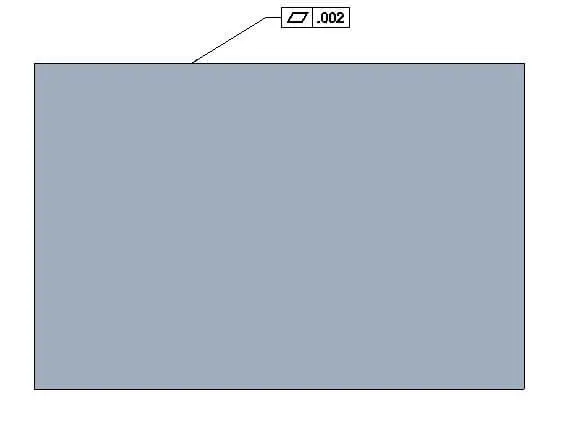

Flatness Symbol

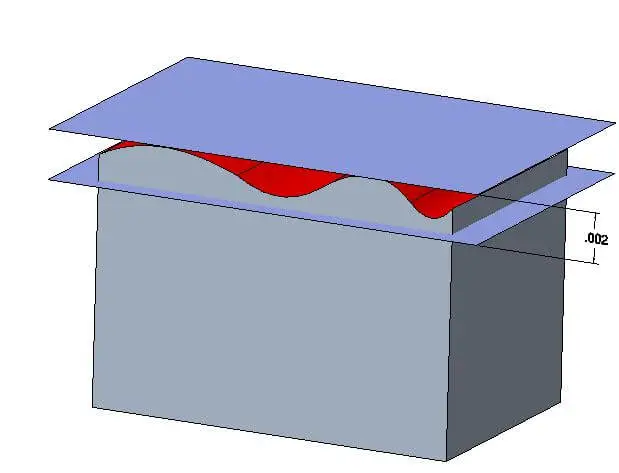

Flatness Tolerance Zone

The flatness tolerance zone consists of two parallel planes that create the boundary within which all specified surface points should lie.

Flatness Tolerance Drawing Callout

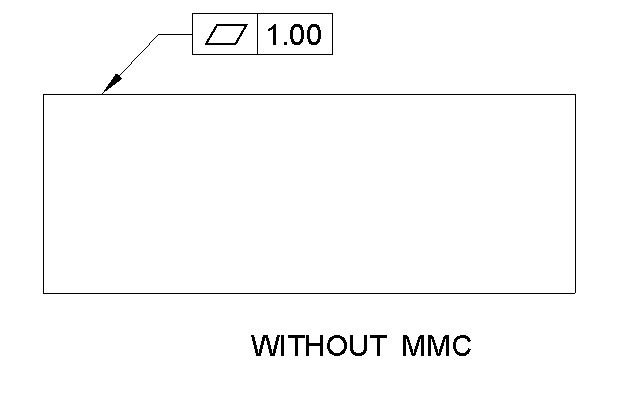

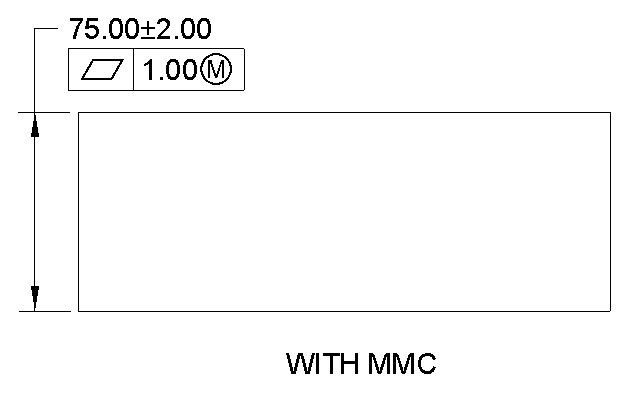

Flatness can be specified with or without MMC or LMC modifiers. Below are two examples that show how the flatness tolerance symbol is specified with and without MMC.

How to measure flatness?

The flatness of a surface can be measured by simply placing the part surface on a granite slab and running a height gauge over it. For accurate measurements, CMMs are the best. Please note that you have to measure points all along the surface as it’s a 3D measurement and not a 2D measurement like straightness.

You may like to read: What is profile tolerance? Definition with examples

When Flatness tolerance is used?

If you want to control the waviness of a surface but don’t want to have tight dimensional tolerance, then flatness tolerance can be an excellent option to achieve good parts. With flatness, you are specifying the amount of deviation allowed for your parts to function correctly. Flatness tolerance is beneficial when two parts are mating surface to surface, and you don’t want any leak in between those parts.

Flatness Tolerance Examples

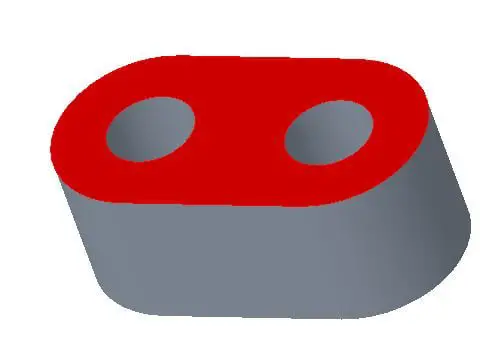

Let’s assume that the red color surface is significant for the part, as shown below. The red surface will mate with other parts, and then bolts will be used to tighten those.

From the function point of view, the assembly should be leakproof. In that case, we need to give a flatness tolerance so that the red surface is relatively flat for having surface-to-surface contact with the other part. The more the surface contact is, the lesser are chances for a leak. We may also need to use a gasket to make the assembly leakproof.

Conclusion: GD&T Flatness

That’s all about Flatness tolerance in this article. I hope I could able to give a brief about GD&T flatness in this article. If you still have some questions or queries, you are always welcome to put up your questions in the comment section, and I will be happy to reply to you back.

You may like to read: What are GD&T rules

Frequently Asked Questions ( FAQ)

What is GD&T Flatness Tolerance?

GD&T flatness tolerance is a form tolerance that controls the form of the surface and specifies the amount of deviation a surface can have against its true form.

Can I use MMC modifier in Flatness tolerance?

Yes, You can use MMC modifier in certain cases.

Do I need to have datum reference for flatness tolerance?

Flatness tolerance is a form tolerance does not need any datum reference.